LVT Flooring Production Line

Be Green By Extrusion!

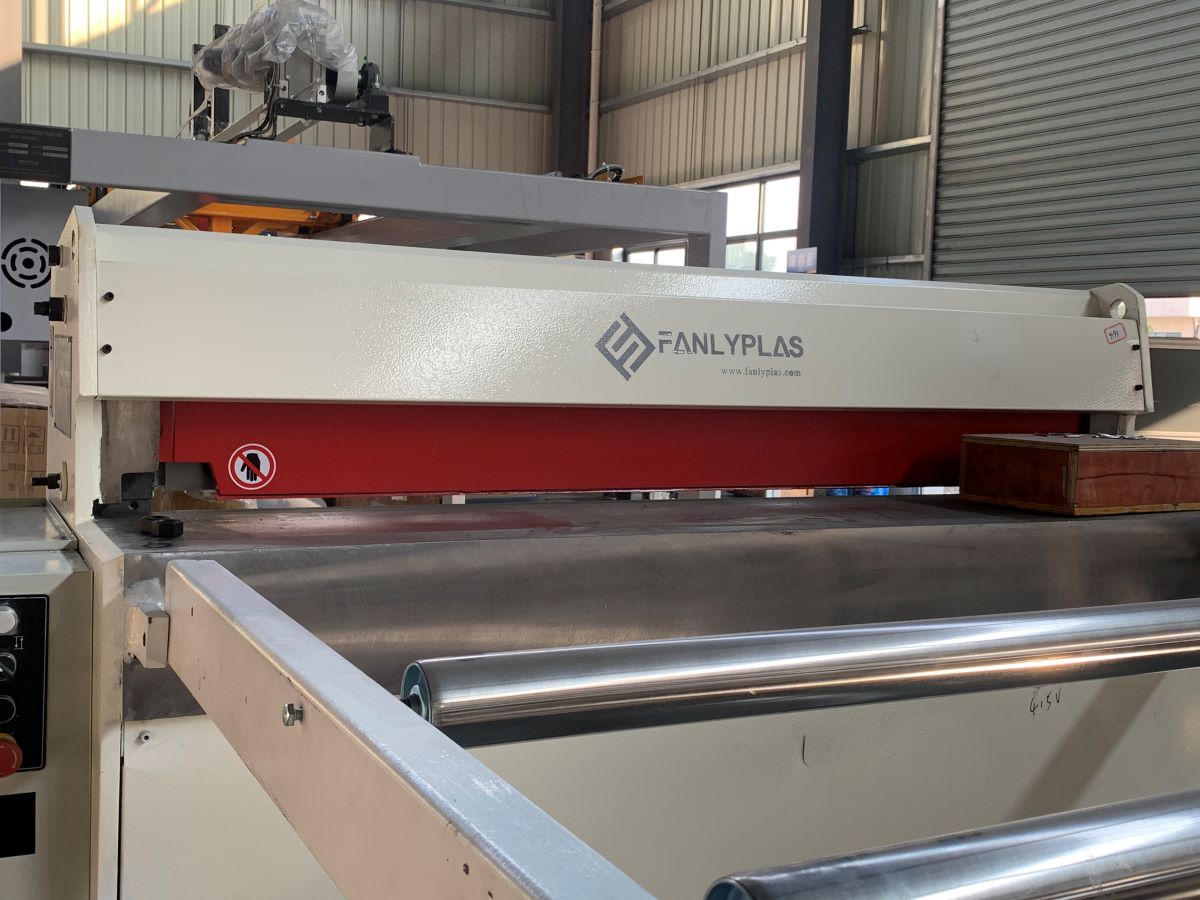

Introduction of FANLYPLAS LVT Flooring Production Line

The LVT flooring production line developed by our company is suitable for extruding LVT floors of various sizes. We also provide customers with formulas and related technologies to help customers complete their projects.

At the same time, we also provide EIR hardware and software services

Complete set of solutions can be provided according to customer needs.

Including:

- Automatic conveying weighing and mixing system

- LVT flooring extrusion line

- UV Coating line

- Annealing/Tempering Line

- LVT Flooring Hydraulic punching

- Automatic packing line

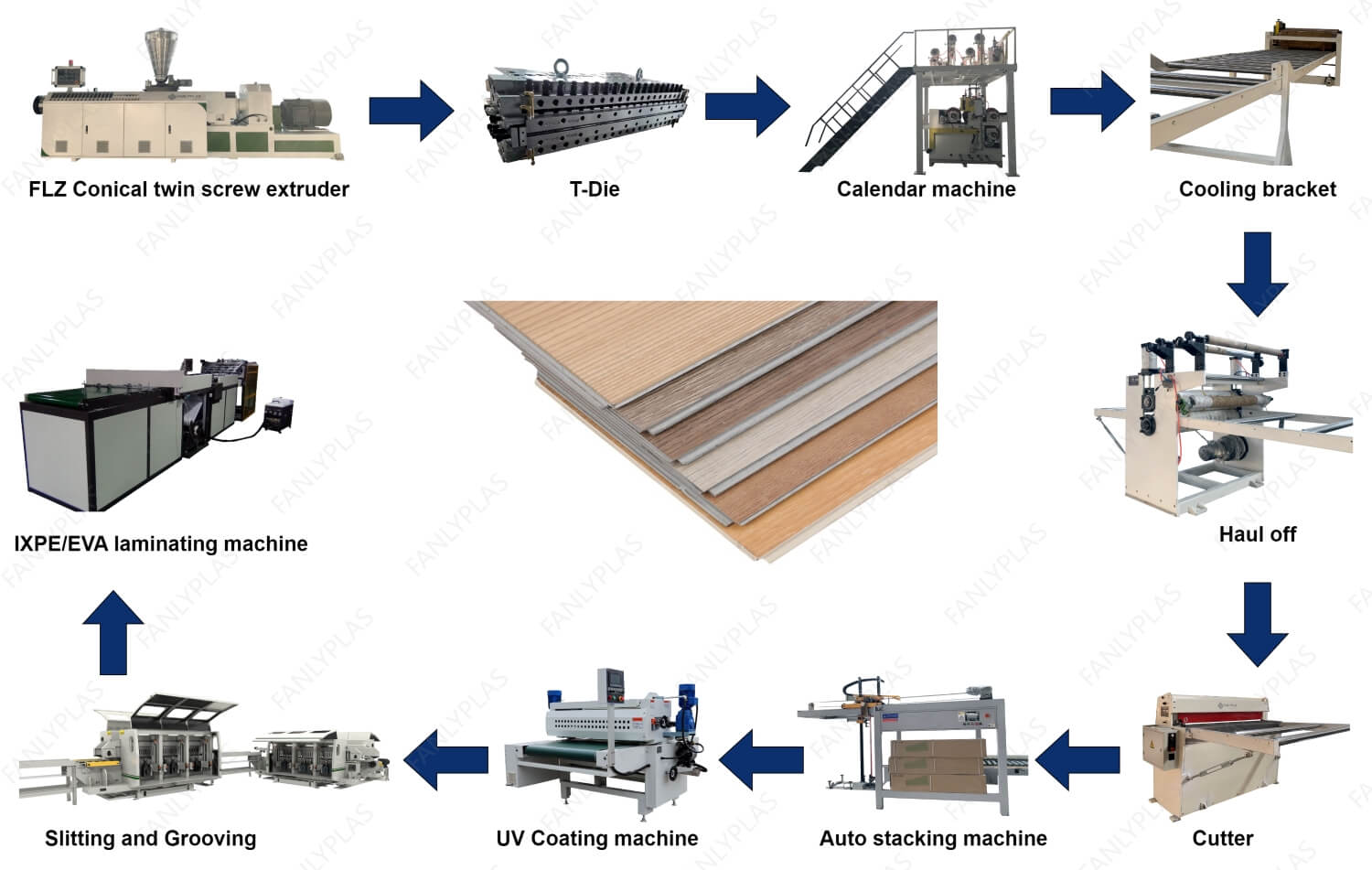

Equipment Composition of FANLYPLAS LVT Flooring Production Line

FANLYPLAS offers customized LVT Flooring Production Line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for FANLYPLAS LVT Flooring Production Line.

Mixer

Extruder

T-Die

Five-roll Calender

Film laminating device

Water tank and trimming cutter

Haul off

High speed shear utter

Auto stacker

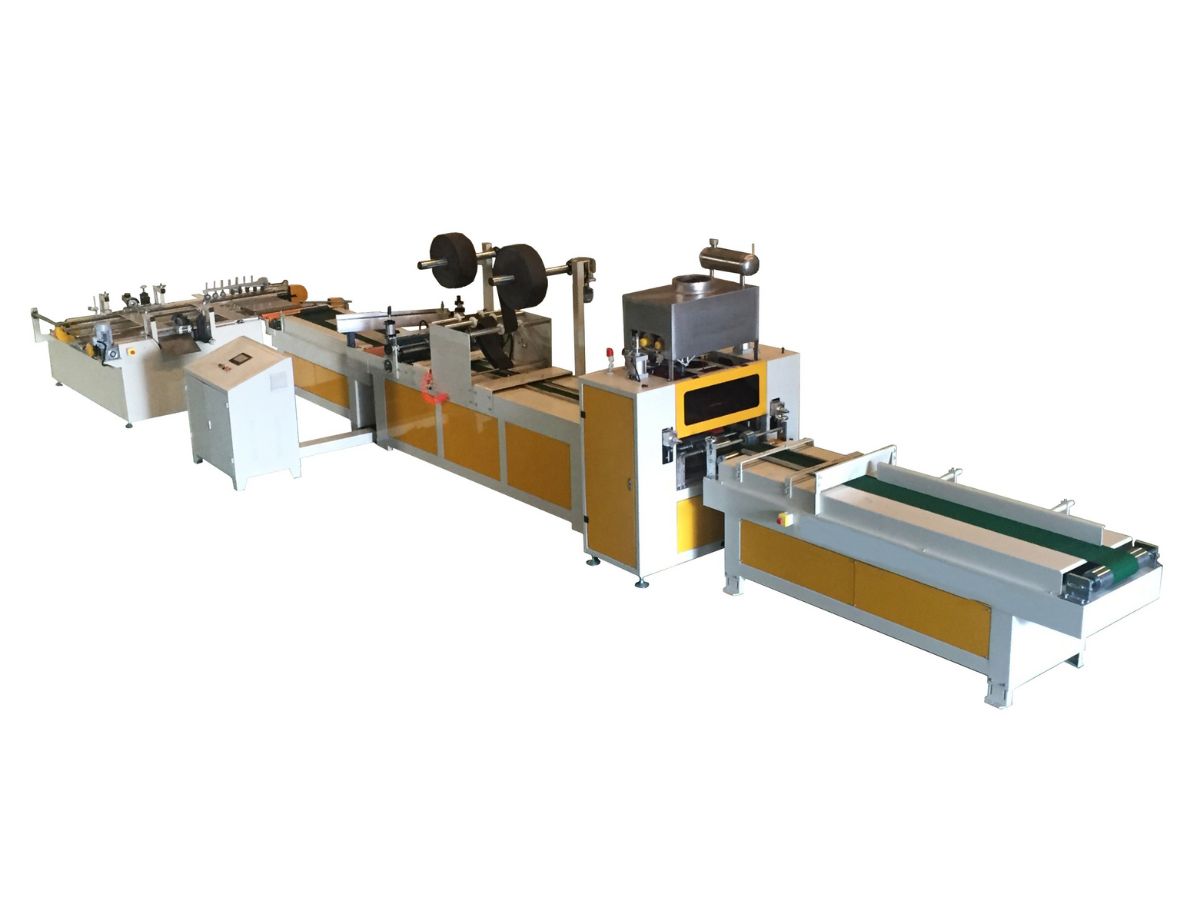

UV Coating line

Annealing/Tempering Line

LVT Flooring Hydraulic punching

Features of FANLYPLAS LVT Flooring Production Line

1.The screw adopts the design of special mixing material function and high plasticization capacity. This guarantees the uniformity of plastic melting, coloring, and high output.

2.T-type die head adopts a double throttling design, which makes them more precise in adjusting the thickness of the sheet.

3.The arrangement of roller can be vertical, horizontal, or free adjusting type, which can give more selection based on different thickness of the sheet.

4.The double loop cooling system and mould temperature controller are adopted to control press-roller temperature, by which sheet thickness can be controlled accurately.

5.The automatic measuring meter instrument can set the length of the sheet.

Characteristics and Applications of LVT Flooring

LVT flooring, or luxury vinyl tile, features excellent durability and water resistance, making it suitable for various settings. It is easy to install, low in maintenance, and available in diverse styles that mimic the aesthetics of natural materials.

1. Residential Use: Ideal for living rooms, kitchens, and bedrooms in homes, offering comfort and style.

2. Commercial Spaces: Suitable for offices, shops, and restaurants due to its high durability and slip resistance.

3. Healthcare Facilities: Perfect for hospitals and clinics because of its waterproof properties and easy cleaning.

4. Educational Institutions: Commonly used in schools and libraries for its easy maintenance.

FAQS

What is the production capacity of the LVT flooring production line?

We have two regular models to choose from, Model 110 and Model 115. Model 110 can produce 1000-1200 kg per hour, and Model 115 can produce 1300-1450 kg per hour.

Can the production line produce sheets of different sizes and thicknesses?

Yes, the line is designed to produce panels in various thicknesses (1-6mm, standard size) and widths between 960-980mm. Other sizes can also be custom made for you.

What raw materials are required for the production line?

The main raw materials are PVC (Polyvinyl chloride), Calcium powder and appropriate processing aids.

How long does it take to install and commission the production line?

Installation and commissioning typically take 10-15 days, depending on the complexity of the production line. Our engineers provide on-site support and training during this period.

What after-sales services do we offer?

We provide comprehensive after-sales services, including equipment maintenance, spare parts supply, remote troubleshooting and on-site technical support. In addition, we also provide operator training, including equipment operation and raw material guidance.

Get Extrusion Solutions Or Service Today?

Just leave your needs & questions here, we will back you in short time. (The more details you leave, the better quotation will reach you soon)