PVC Edge Banding Extrusion Line

Features of PVC Edge Banding Extrusion Line

Fanlyplas offers customized Edge Banding Extrusion Line according to different raw material, final product size and machine capacity. Except PVC edge banding extrusion line, we can also provide ABS Edge Banding Extrusion line, Acrylic Edge Banding Extrusion line and PP Edge Banding Extrusion Line.

Plastic edge band extruded sheets can be used in different furniture, such as table, coffee table, wardrobe, garden furniture, television stand and etc. Fanlyplas can provide best solutions for different ABS, PP and PVC edge band final products.

FANLYPLAS could customize printing patterns as per customer’s requests and offer printing machine lines correspondingly.

FANLYPLAS could design and fabricate molds as per customer’s drawing, and offer on-line printing/gluing/UV coating downstream machines to complete the production process.

- FANLYPLAS could also offer embossing unit to enrich the variety of PVC edge bands.

Plastic Edge Banding Extrusion Line Types

The type of plastic edge band extrusion machine lines can be categorized according to raw material or product types. We can categorize the plastic sheet extrusion machines according to its application. Let us explain more about our plastic edge band extrusion machine according to raw material and product types.

Plastic Edge Banding Production Line by Raw Material

PVC Edge Band Extrusion Line

PVC raw materials are 100% recyclable. PVC is also highly fire resistant. PVC Edge Banding Extrusion Line is a fairly common edge banding production line as it is favored by large volume edge banding producers.

PP Edge Band Production Line

PP has high resistance against chemical materials, so it is preferred in kitchen worktops. Also PP has more flexibility, therefore PP edge banding production line also preferred for small-radius applications.

ABS Edge Band Production Line

ABS can be called more green plastic raw material which means environmentally friendly because of burning and extermination parameters. ABS has most of the properties of PVC, but ABS is less dense, does not contain chlorine in its composition, and is not flame retardant.

Acrylic Edge Band Extrusion Line

Acrylic edge band can be also called PMMA or 3D. It is preferred because of mostly resistance against water, then it is used as isolation material as water seal on the corner of furniture. Also it has the advantage of hard-wearing resistance.

Plastic Edge Band Extruder Machines by Final Shapes

Two Color Edge Band Extrusion

Two color edge band extruded materials is preferred mostly because of the decorative reasons. We also provide Co-Extruder with our edge banding production line for having solid two colors on plastic edge banding production process.

Solid Color Edge Band Extrusion

Solid color edge band production is done by typical edge banding production line. For having different color, color pigment is used on the process. We are adding dosing system on our edge band extruder machine for having stability on colors for solid edge band production process.

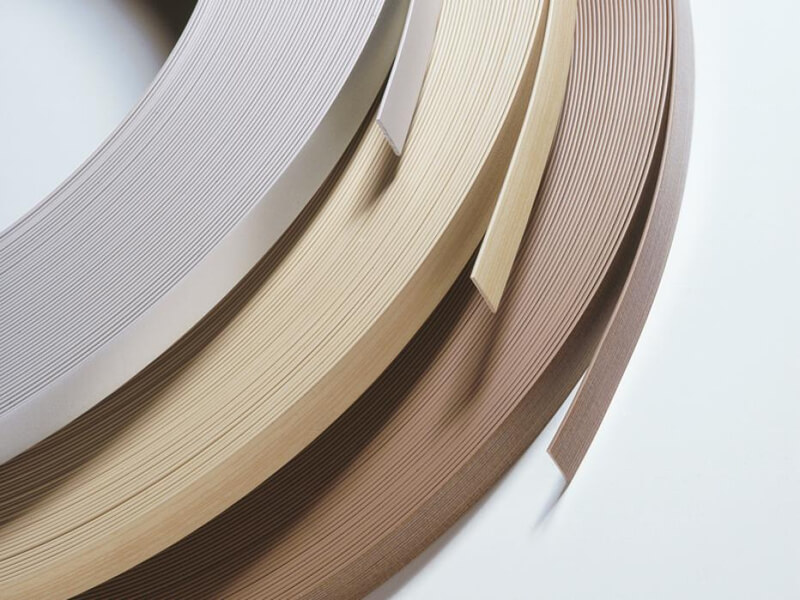

Wood Effect Edge Banding Production

As we all know, wood effect edge banding production is the most common type in furniture industry. Having stable color is very important. Our edge banding production line provides excellent solutions for customers.

Single Edge Band Extrusion Line

Normally edge banding production process is preferred mostly as sheet production and then slitting into pieces process. Plastic edge band corners can have radiuses and smooth corners. This can be customized according to customer needs.

Get Extrusion Solutions Or Service Today?

Just leave your needs & questions here, we will back you in short time. (The more details you leave, the better quotation will reach you soon)