Acrylic Laminate Sheet Production Line

Features of Acrylic Laminate Sheet Production Line

1.FANLYPLAS’ Acrylic Laminate Sheet Production Line can continuously produce single-layer and multi-layer Acrylic Laminate Sheets. The screws are specially designed according to the rheological property of raw material, precise melt pump system, and T-die, which makes the extrusion melt even and stable and the sheet has excellent optical performance. A precise calendar system guarantees the mechanical & physical properties of sheets.

2.Extruder: According to the different materials, a venting single-screw extruder is selected. The screw adopts a special mixing function and a precise temperature control system to ensure high plasticization, high-yield and stable extrusion of plastics. Temperature control ±1℃ can accurately control the plasticization process and the thickness and flatness of the sheet.

3.The hanger-type die head adopts a page double throttling design, which is convenient for adjusting the flow distribution to be uniform, and the thickness of the extruded sheet is adjusted more accurately.

Details of Production Line

1.Three-roll calender: According to the thickness of the plate, a 45° inclined three-roller, vertical three-roller or horizontal three-roller calender is used. The temperature control of the three rollers is independent of each other, the gap between the rollers can be adjusted freely, and the special design of the adjustable angle of the middle roller ensures the calendering effect and the thickness uniformity of the plate (sheet).

2.The thickness control of the plate adopts screw adjustment and two-way adjustment of the pressure wheel to accurately control the thickness of the plate. The independently controlled roller temperature control system can accurately control the temperature of the pressure roller to make the plate uniform in thickness.

3.Cooling roller bracket: Equipped with corresponding cooling guide rollers to achieve better cooling effect. It is also equipped with a trimming device to ensure the fixed width and edge quality of the plate.

4.Transverse cutting machine: used for length cutting, the cutting accuracy is less than 2mm, and alloy blades or hard alloy saw blades are used. When cutting, it is synchronized with the plate, so as to ensure the quality of the plate section and the long-term stability of the cutting action.

5.Winding machine: It adopts high-torque motor and friction winding. The speed and winding tension can be adjusted at will. Other forms of winding can also be provided according to user needs.

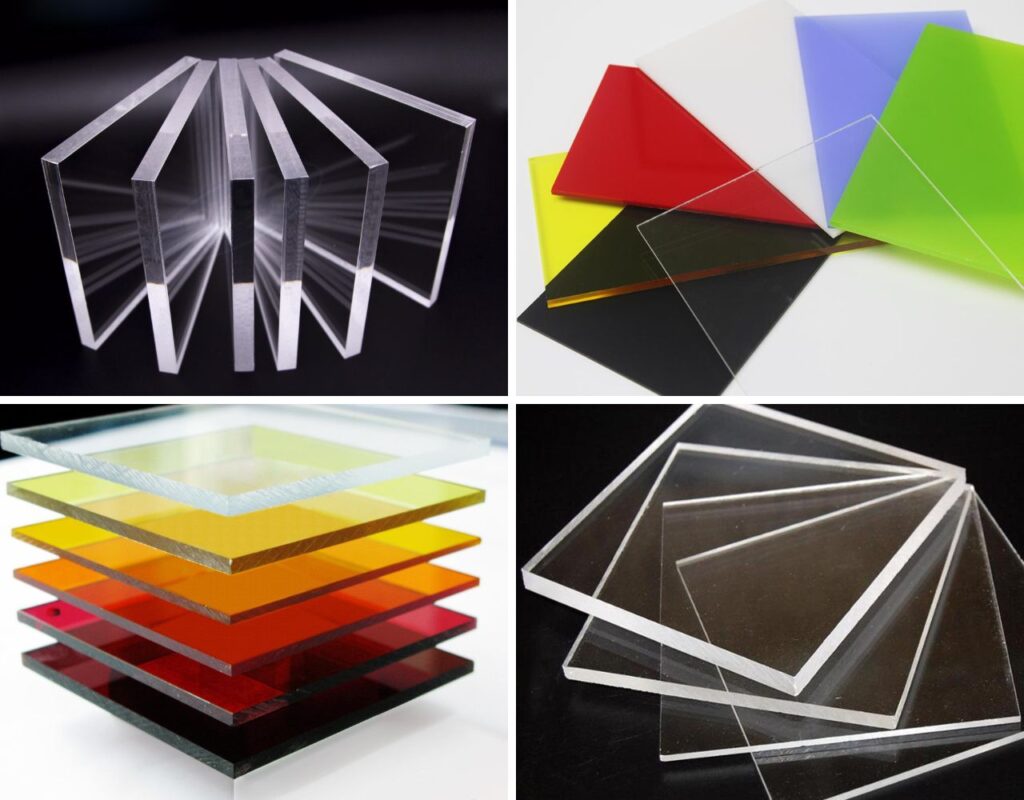

Application of Acrylic Laminate Sheet

The width of the acrylic laminate sheet produced is less than 2600mm, the thickness is 0.8-10mm, and the light transmittance is good. Its products are widely used in refrigerators, air conditioners, advertising, construction, environmental protection chemicals, sanitary ware, instrument parts, lamps, decoration, building materials, aircraft, auto parts, medical equipment, craft products, electrical insulation materials, specimens, signs, and various light industries, cultural and educational, daily necessities and other fields.

Get Extrusion Solutions Or Service Today?

Just leave your needs & questions here, we will back you in short time. (The more details you leave, the better quotation will reach you soon)