PVC/WPC Door Frame Extrusion Line

Be Green By Extrusion!

Introduction of PVC/WPC Door Frame Extrusion Line

1. PVC WPC Door Frame Extrusion Machine use PVC and Wood Powder Mixed Material, It can produce hollow type and solid type door frame profile. By changing moulds.

2. The machine can be customized by different requirements and applications.ThePVC WPC Door Frame Extrusion Line adopts special screw and barrel, which can make WPC profile and PVC profile.

3. The PVC WPC Door Frame Extrusion Line is equipped with a conical twin-screw extruder. This machine has the advantages of uniform thawing of materials, fast shear rate, high output and long service life.

4. Beyond door frames, our versatile PVC/WPC extrusion line can also be adapted to produce a variety of other building and decorative profiles. With slight modifications to the die head and downstream equipment, the line can manufacture PVC/WPC window profiles, skirting boards, wall panels, and decorative trims.

Component Units of the PVC/WPC Door Frame Extrusion Line

FANLYPLAS offers customized PVC/WPC door frame extrusion line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for FANLYPLAS PVC/WPC door frame extrusion line.

1. Material Recycling System

- Crusher and pulverizer

- WPC Granulator (Optional, depending on the raw material form)

2. Mixing System

- Horizontal/Vertical Mixer

Feeding System

3. Extrusion System

- Twin-Screw Extruder

- Single-Screw Extruder (Optional, for co-extrusion)

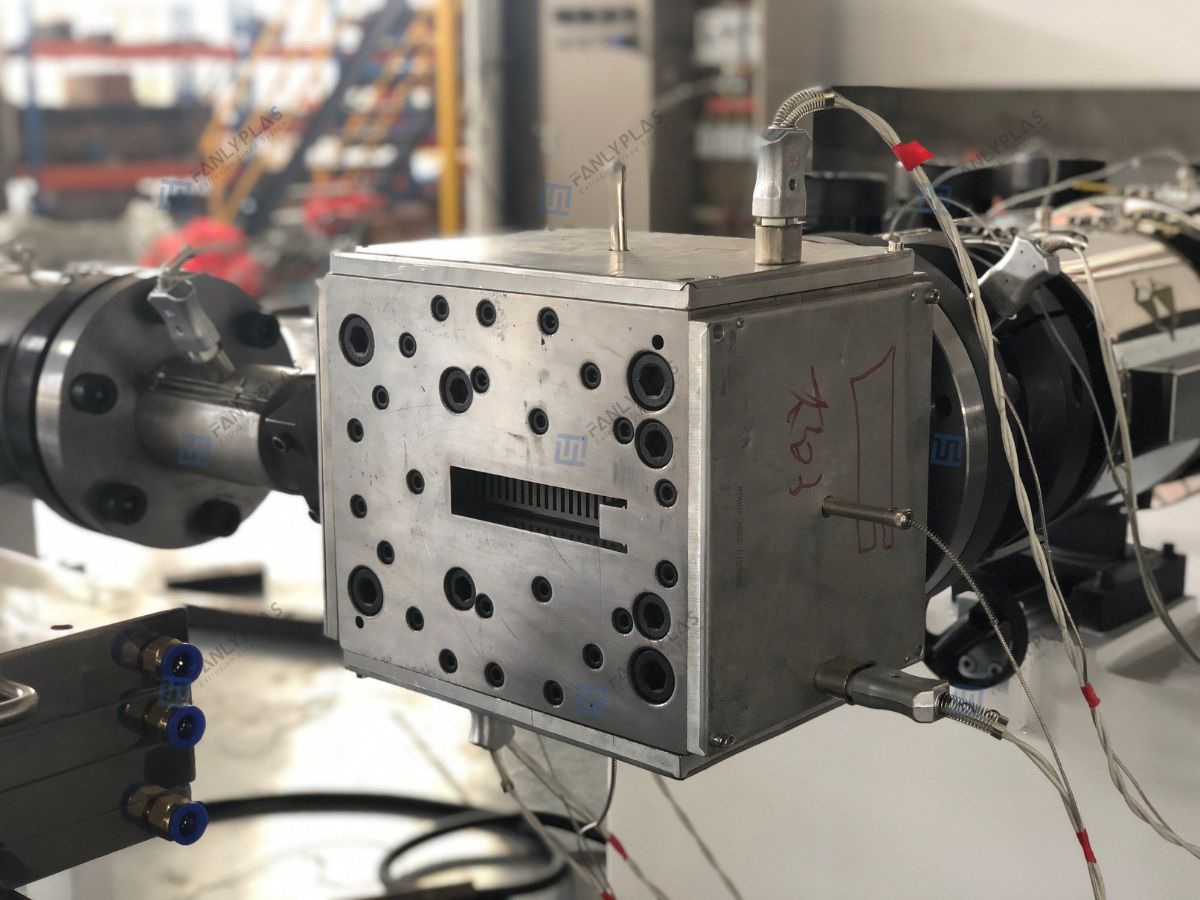

4. Molding System

- Extrusion Mold

5. Vacuum Calibration System

- Calibrator

6. Cooling System

- Water Cooling Tank System

7. Hauling and Cutting System

- Hauling Machine

- Cutting Machine

9. Stacking System (Optional)

- Automatic Stacker

The PVC/WPC Door Frame Extrusion Line Production Process

1

2

3

4

Application of PVC/WPC Door Frame

As a mature product developed from PVC door frame. Fanlyplas designed a more strong product of solid WPC door frame with excellent extrusion technology makes product less bending coefficient and less shrinkage for heavy door use.

PVC/WPC Door Frame Advantages:

1.Moisture protection, anti-water, mildew proof, avoid worm-eaten, anti-UV, color consistency.

2.Durability, sun-proof, wear-resistant, high strength, high density, water proof.

3.No painting, high wood texture, easy installation, without formaldehyde, low maintenance cost.

4.Anti-skid, various style, distortion and crack resistance.

5.Durable life is 5-10 times than solid wood.

6.PVC/WPC door frame is mainly used for door, indoor home decoration, indoor and outdoor guard-rail and other decorative material. It is an ideal choice for decoration of villa, home, hotel, shopping mall and office.

Q&A

What types of raw materials can be used in the PVC/WPC door frame extrusion line?

Required materials: PE+calcium carbonate+wood powder+additives.

What is the size of the produced PVC/WPC door frame?

Size of PVC/WPC door frame: <300mm or customerized.

For final profiles size from PVC/WPC door frame extrusion machine, it is according to clients’ requirement.

What is the production capacity of the PVC/WPC door frame extrusion line?

Capacity: 160-350kg/h.

What is the power of PVC/WPC door frame extrusion line?

Main motor power: 37-55kw

Why Choose Production Line from FANLYPLAS?

1

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality PVC/WPC door frame extrusion lines, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent PVC/WPC door frame to help you stand out in the market.

2

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

3

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known mechanical equipment production line brand from Shanghai, continuously invests in R&D to constantly optimize products and technologies. Choose us, and you will get reliable products and a long-term partnership.

Contact Us for Your Solution!

Thank you for your interest in FANLYPLAS PVC/WPC door frame extrusion lines! If you have any questions or requirements regarding our products, or if you would like to obtain a more detailed customized solution, please fill out the contact form below with your contact information and specific needs. Our professional team will contact you as soon as possible to provide you with the best quality service and support.