PC ABS Sheet Extrusion Line

Be Green By Extrusion!

Applications and Features of FANLYPLAS PC ABS Sheet Extrusion Line

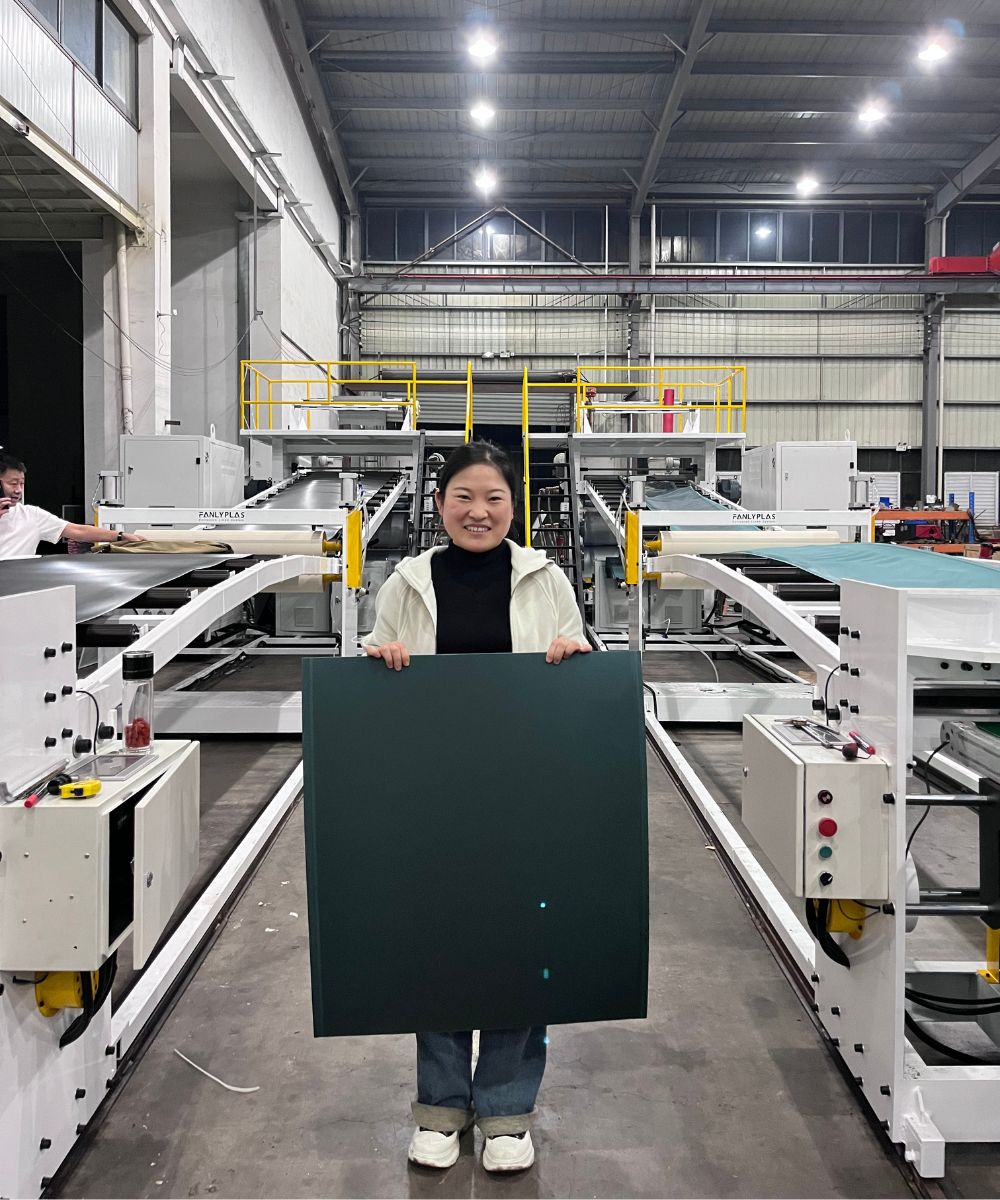

Based in our stragtic cooperation with core components supplier and our own designs, we established a very strong system whatever in technology, machine quality stability and supplying capacity. With many successful cases we have supplied whatever in China local market or foreign market. Our PC ABS Sheet Extrusion Line is a state-of-the-art manufacturing solution designed for producing high-quality PC/ABS sheets.Our extrusion line integrates advanced technologies to ensure excellent performance of screw designs, high efficiency, and precise control over sheet thickness and surface quality. With its reliable design and innovative features.

1.High Precision Production: The line ensures uniform thickness and consistent surface quality with advanced calibration and cooling systems.

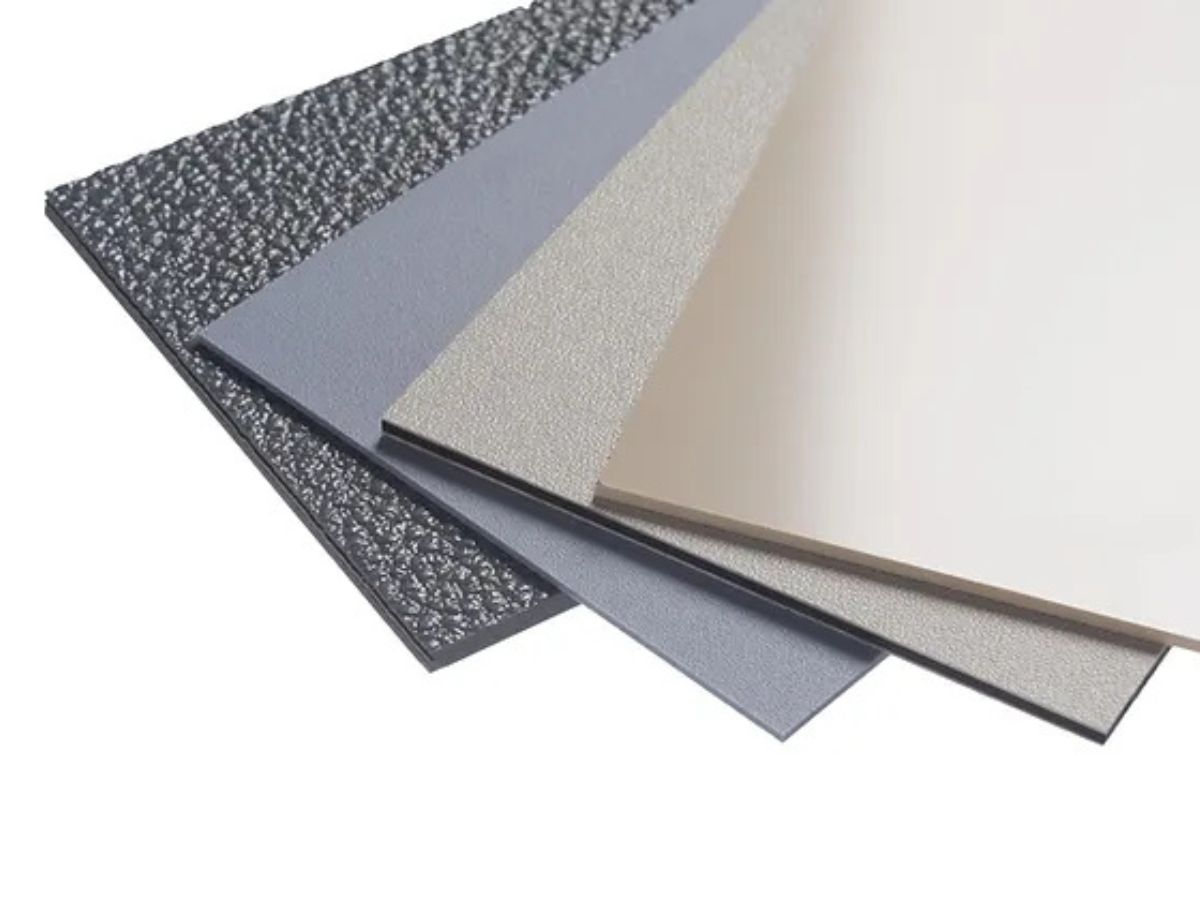

2.Customizable Design: Flexible configuration options allow for the production of sheets in various sizes, thicknesses, and surface finishes to meet diverse industry needs.

3.Energy Efficiency: Equipped with energy-saving components, the production line reduces power consumption while maintaining high output.

4.User-Friendly Operation: Automated controls and intuitive interfaces simplify operation, minimizing labor requirements and enhancing productivity.

Equipment Composition of PC ABS Sheet Extrusion Line

FANLYPLAS offers customized PC ABS Sheet Extrusion Line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for FANLYPLAS PC ABS Sheet Extrusion Line.

Dehumidifier and dryer system

Extruder

Die Head

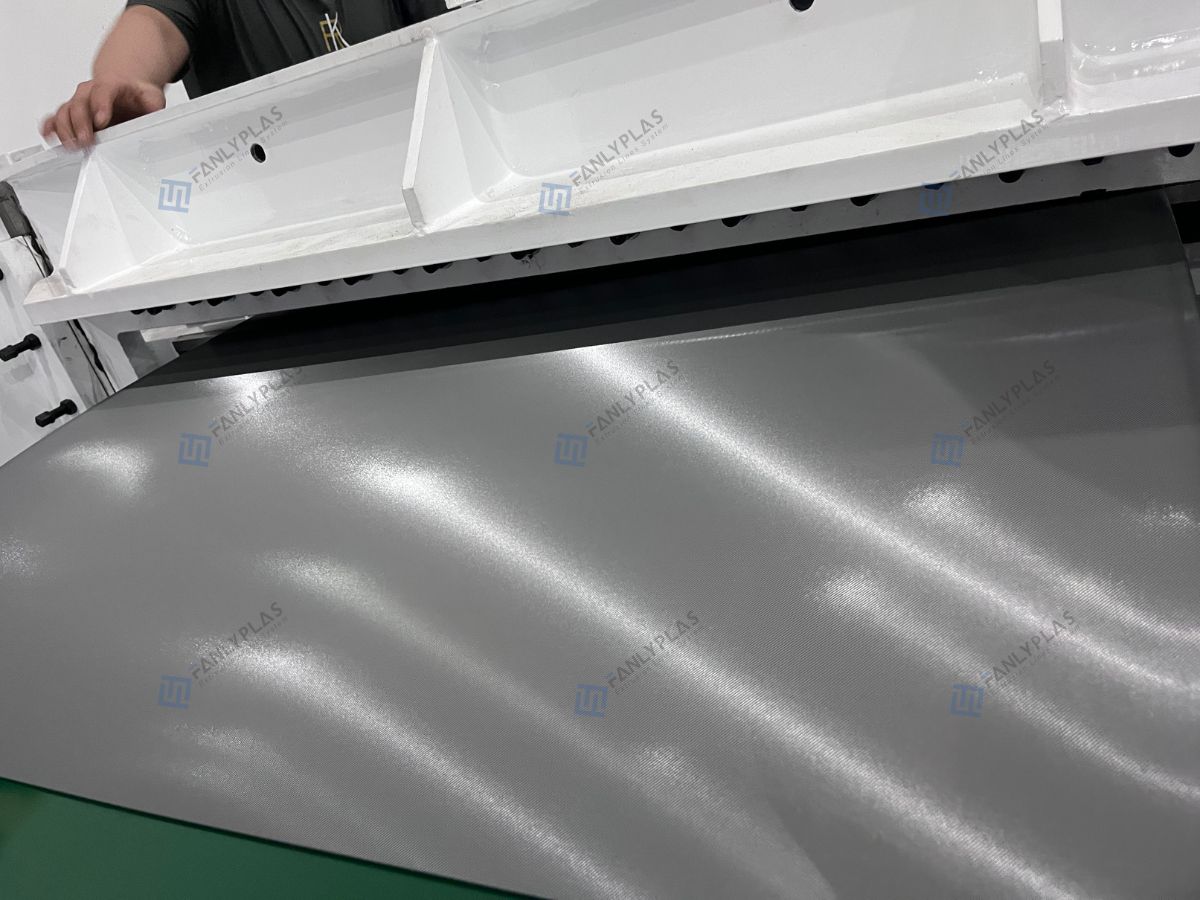

Three-Roller Calender

Lamination Unit Platform

Cooling Bracket

Tractor

Cutting Machine

FANLYPLAS PC ABS Sheet Extrusion Line Workflow

1.Raw Material Loading

2.Material Melting and Mixing

3.Sheet Forming

4.Surface Refinement

5.Cooling and Stabilization

6.Cutting and Finishing

Performance and Applications of PC Sheets

PC Sheet Performance:

PC (polycarbonate) sheets are known for their high impact resistance, transparency, and thermal stability. They offer excellent UV protection, flame retardancy, and are lightweight yet highly durable. PC sheets maintain clarity and strength under extreme temperatures, making them ideal for demanding applications requiring optical clarity and mechanical strength.

Applications of PC Sheets:

1.Construction: Used in roofing, skylights, and sound barriers due to its transparency and durability.

2.Automotive: Applied in headlight covers and interior panels for their lightweight and strength.

3.Electronics: Used in protective covers and components for their insulating properties.

4.Safety Equipment: Widely used in bulletproof glass and helmets for impact resistance.

Performance and Applications of ABS Sheets

ABS Sheet Performance:

ABS (Acrylonitrile Butadiene Styrene) sheets feature excellent toughness, heat resistance, and ease of processing. They provide a good balance of strength, rigidity, and surface finish, making them versatile and cost-effective. ABS sheets are also resistant to chemicals and provide stable performance in both indoor and outdoor conditions.

Applications of ABS Sheets:

1.Automotive: Used in dashboards, trims, and consoles for their toughness and easy molding.

2.Consumer Goods: Common in luggage, toys, and home appliances for their durability.

3.Medical Equipment: Used in enclosures and housings due to their chemical resistance.

4.Electronics: Used in keyboard frames and electronic housings for their rigidity and finish.

Q&A

What is the maximum sheet width and thickness your production line can produce?

Our PC ABS Sheet Extrusion Line can produce sheets with a maximum width of 2100mm and a thickness range of 1mm to 12mm. Customizations are available to meet your specific requirements.

What types of raw materials are compatible with this extrusion line?

The production line is designed to handle high-quality PC (Polycarbonate) and ABS (Acrylonitrile Butadiene Styrene) raw materials, as well as their blends. It ensures efficient processing and consistent quality for various formulations.

How do you ensure the quality of the sheets produced by this line?

Our production line incorporates advanced technologies like precise screw design, high-quality die heads, and automated calibration systems. Additionally, rigorous testing and quality control protocols are implemented to ensure consistent thickness, surface finish, and mechanical properties.

How energy-efficient is your production line?

Our extrusion line is equipped with energy-saving components, such as high-efficiency motors, optimized heating systems, and smart control technologies. These features minimize energy consumption while maintaining high output.

What kind of after-sales service do you provide?

We offer comprehensive after-sales support, including on-site installation, training for operators, regular maintenance, and 24/7 technical assistance. Spare parts are also readily available for quick replacement.

Why Choose Production Line from FANLYPLAS?

1. Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality PC ABS sheet extrusion lines, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent PC ABS sheet to help you stand out in the market.

2. Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

3. Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known mechanical equipment production line brand from Shanghai, continuously invests in R&D to constantly optimize products and technologies. Choose us, and you will get reliable products and a long-term partnership.

Contact Us for Your Solution!

Thank you for your interest in FANLYPLAS PC ABS sheet extrusion lines! If you have any questions or requirements regarding our products, or if you would like to obtain a more detailed customized solution, please fill out the contact form below with your contact information and specific needs. Our professional team will contact you as soon as possible to provide you with the best quality service and support.