PVC Ceiling Panel Extrusion line

Be Green By Extrusion!

Features Of FANLYPLAS PVC Ceiling Panel Extrusion Line

1.FANLYPLAS PVC ceiling panel production line is a high-performance manufacturing system designed for production with stable quality and low defective rates. It has high output, stable extrusion pressure, high precision, good plasticization, long life, and strong screw self-cleaning performance.

2.PVC extruder for plastic ceiling panel have applied oil cooling system. Barrel is cooled by special wind cooling system.

3.Ceiling Panel extruder plant system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plastic city performance and material quality.

4.Plastic Extruder machine for ceiling panel is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

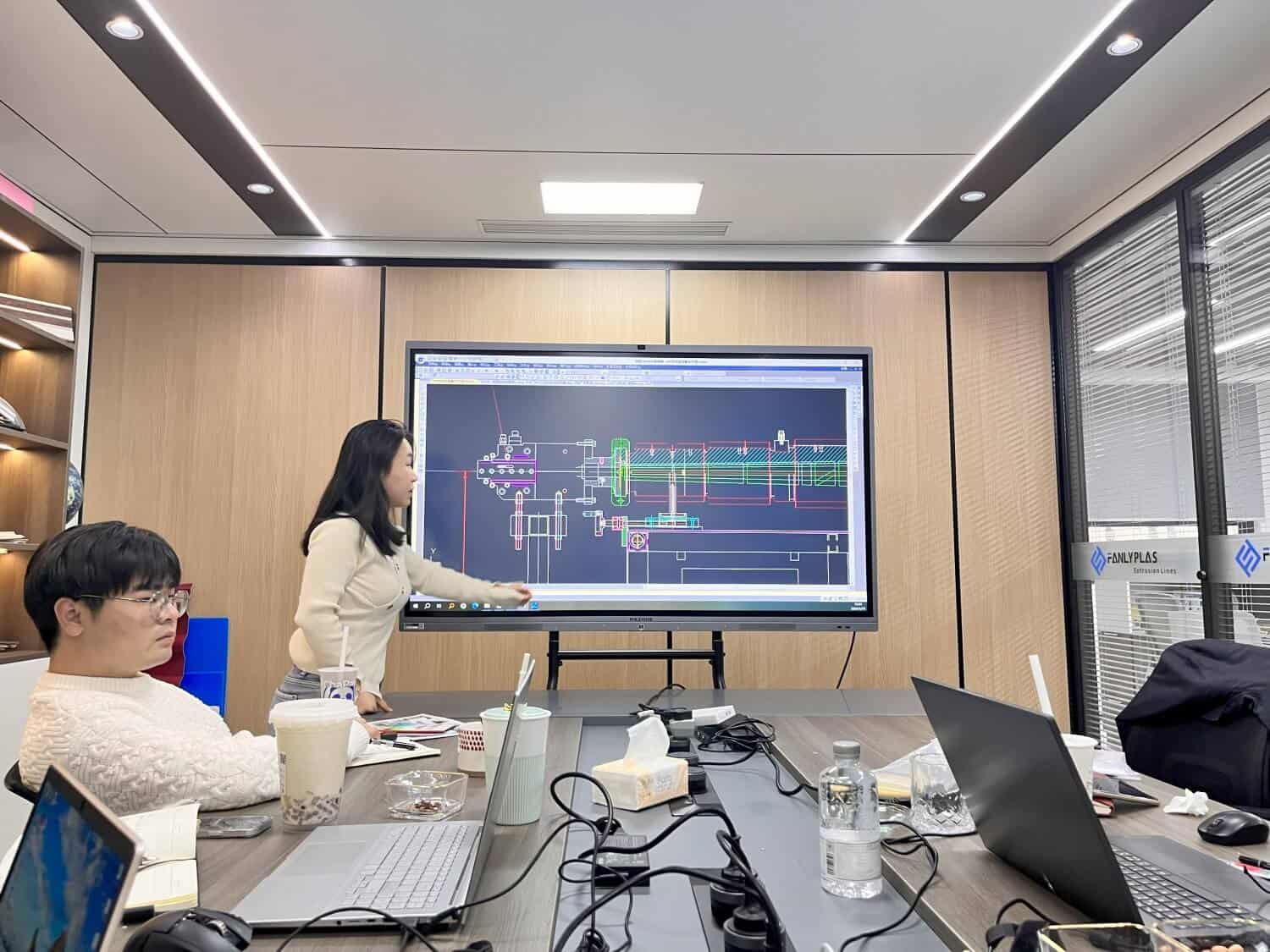

Equipment Composition of FANLYPLAS PVC Ceiling Panel Extrusion line

FANLYPLAS offers customized PVC Ceiling Panel Extrusion line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for FANLYPLAS PVC Ceiling Panel Extrusion line.

Extruder

Mould

Haul-off

Film Laminating/Hot stamping Machine

Knife Cutting Machine

Automatic stacker

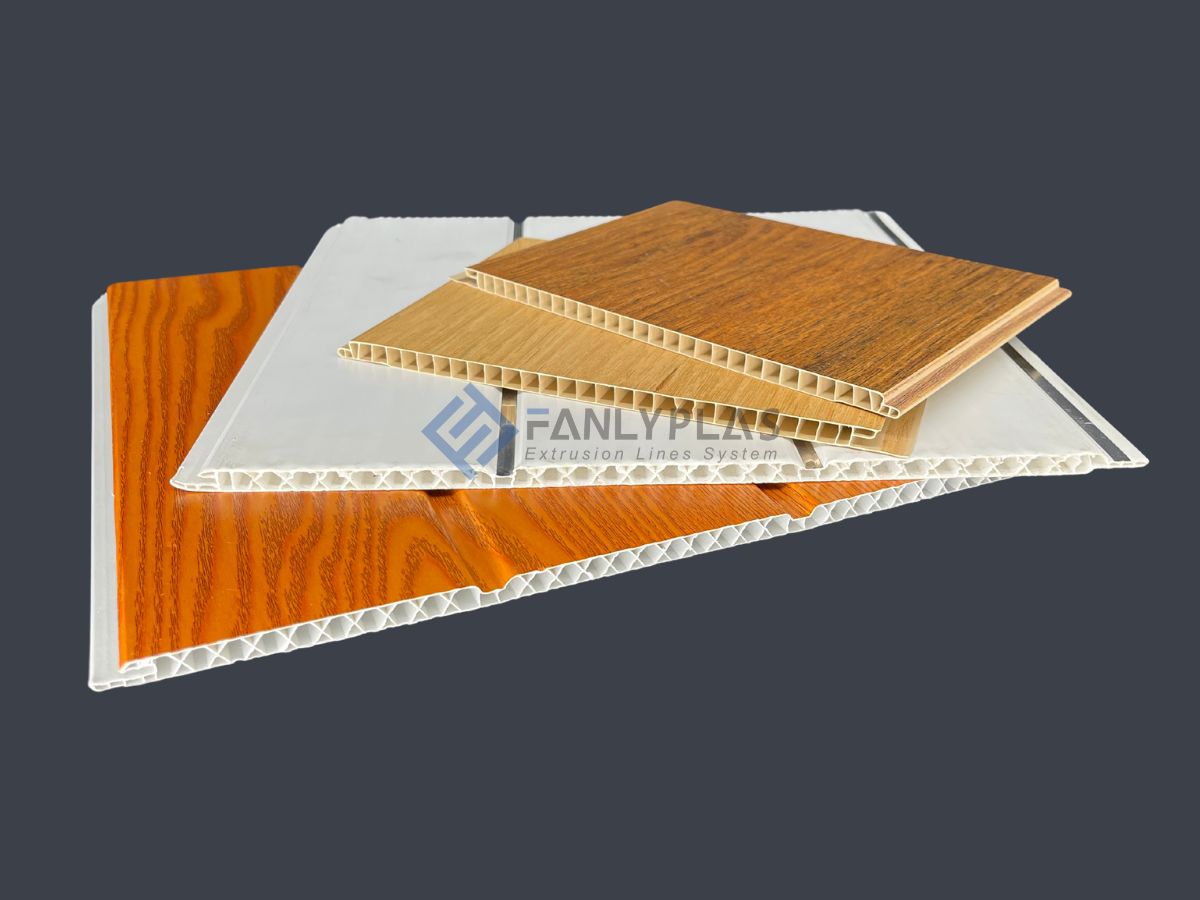

Application And Characteristics Of PVC Ceiling Panel

1.PVC ceiling panels can be produced in many colors and sizes through production processes and can be used as wall panels and ceiling panels.

2.The width range of finished product range from 100mm to 600mm.

3.The surface of PVC Ceiling panel can be treated by double color roller printing, UV lacquer coating, hot stamping printing, or by lamination, which can make marble, wooden design on product surface.

4.PVC panel can be used in house decoration, office decoration, kitchen room, washing room decoration, it’s environment-friendly raw materials and can be recycled, it has wide market prospect.

5.PVC ceiling panels are 100% waterproof. This makes them ideal for areas that experience high levels of condensation and humidity, such as bathrooms and kitchens. Being waterproof they create a cleaner, healthier environment for those in your home.

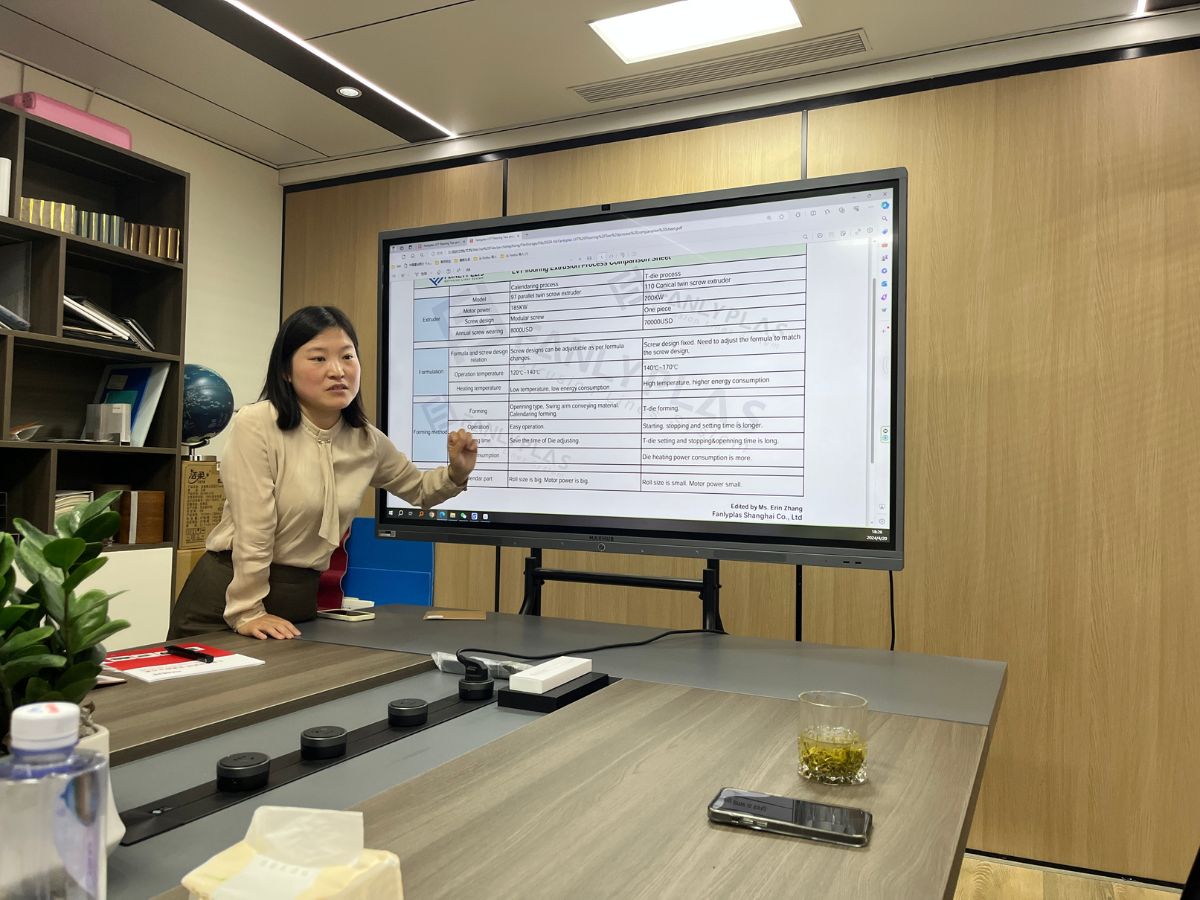

Why Choose FANLYPLAS for Your PVC Ceiling Panel Extrusion line ?

Industry Expertise: With years of experience in plastic extrusion technology, FANLYPLAS is a trusted partner for businesses worldwide. We design and manufacture extrusion lines that deliver precision, efficiency, and consistency, helping you stay ahead of the competition.

Comprehensive Solutions: From the initial concept to full-scale production, FANLYPLAS offers an all-in-one solution. Our services include consultation, machinery design, equipment manufacturing, installation, and ongoing support, ensuring a smooth process from A to Z.

Global Reach: Located in Shanghai, China, FANLYPLAS serves over 20 countries, providing top-tier solutions to a diverse international customer base. We are equipped to handle both large-scale industrial demands and specialized, smaller-scale custom projects.

Get Extrusion Solutions Or Service Today?

Just leave your needs & questions here, we will back you in short time. (The more details you leave, the better quotation will reach you soon)