UPVC Window And Doors Profile Extrusion Line

Custom your automatic production line! Made to order. Made to fit.

Introduction of UPVC Window And Doors Profile Extrusion Line

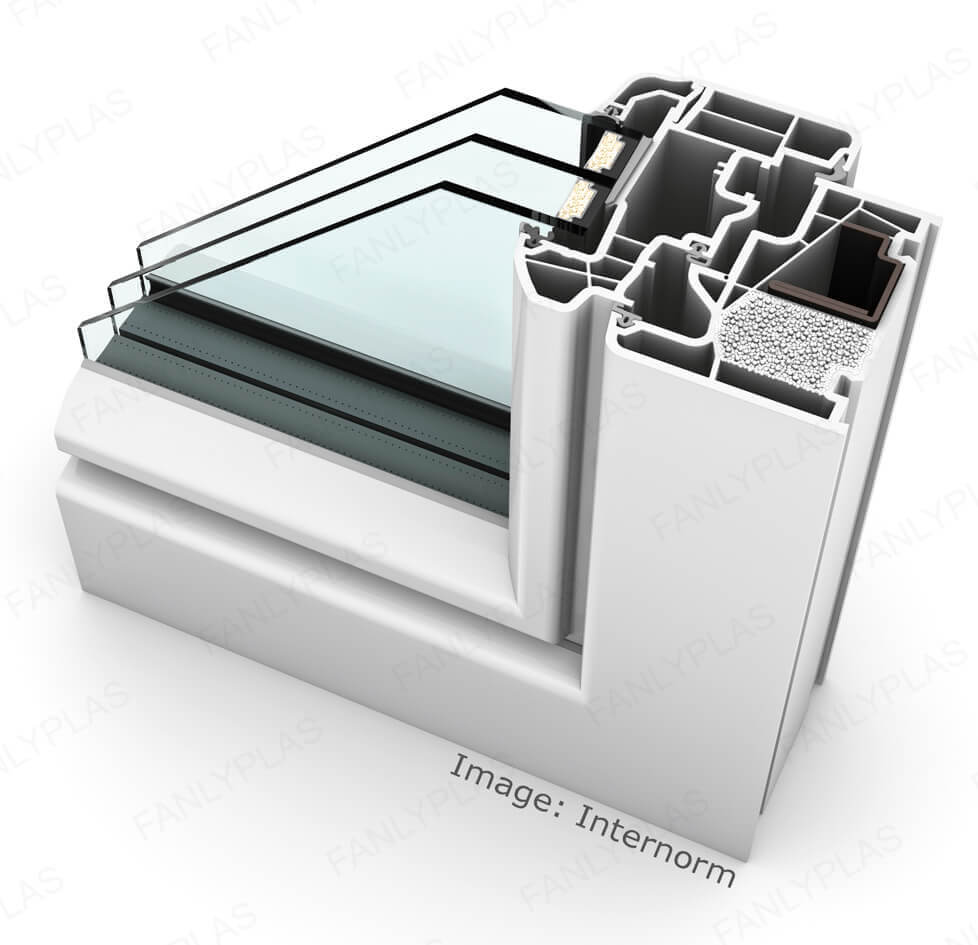

1.This machine is used to produce UPVC profiles for windows and doors with different series by switching related moulds.

2.specialized conical twin screw extruder with unique screw design for high quality plaisitising of PVC materials to ensure produce high strengh of PVC window profiles.

3.Tractor carries some our unique technologies like the lift/down system. The pulling force is strong and very stable.

4.The vacuum forming table is adopted large vortex cooling system for proper profile forming requirement.

5.FLZ series counter-rotating twin screw extruders and SJP series parallel twin screw extruders can process standard thermoplastic profiles and high speed profiles with different dimensions. With unique sizing and cooling unit to make sure the stable production and excellent quality.

Features of UPVC Window And Doors Profile Extrusion Line

Fanlyplas machine main characteristics:

1.Highly rigid structure due to the sturdy construction and vibration- free support base.

2.Ergonomic controls at the operator’s disposal.

3.Sizers support bench, housed in a water collection trough made in SS.

4.High capacity vacuum units for the “combined” air/water calibration when the profile fast cooling is required.

5.Water/air silenced separators, essential for the combined calibration.

6.Customized version available on request with additional vacuum groups, profile drying system and other accessories.

7.The equipment slides on rails trough double speed motor driven jack, 600 mm useful traverse.

8.Models suitable for a pulling force up to 5000 kg.

Get Extrusion Solutions Or Service Today?

Just leave your needs & questions here, we will back you in short time. (The more details you leave, the better quotation will reach you soon)