WPC Indoor Louvers/Wall Panel Production Line

Be Green By Extrusion!

Introduction of Our WPC Indoor Louvers Line

1

2

3

Other Products the Production Line Can Manufacture: In addition to WPC indoor louvers and wall panels, this versatile production line can also be adapted to produce a range of other WPC products. These include various WPC profiles such as skirting boards, door frames, and window profiles, as well as WPC decking for outdoor use and WPC fencing for gardens and other enclosures. With suitable die changes and adjustments, you can expand your product portfolio and cater to a broader market with this single production line.

Component Units of the WPC Indoor Louvers Line

FANLYPLAS offers customized WPC indoor louvers/wall panel production line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for FANLYPLAS WPC indoor louvers/wall panel production line.

1. Material Recycling System

2. Mixing System

3. Extrusion System

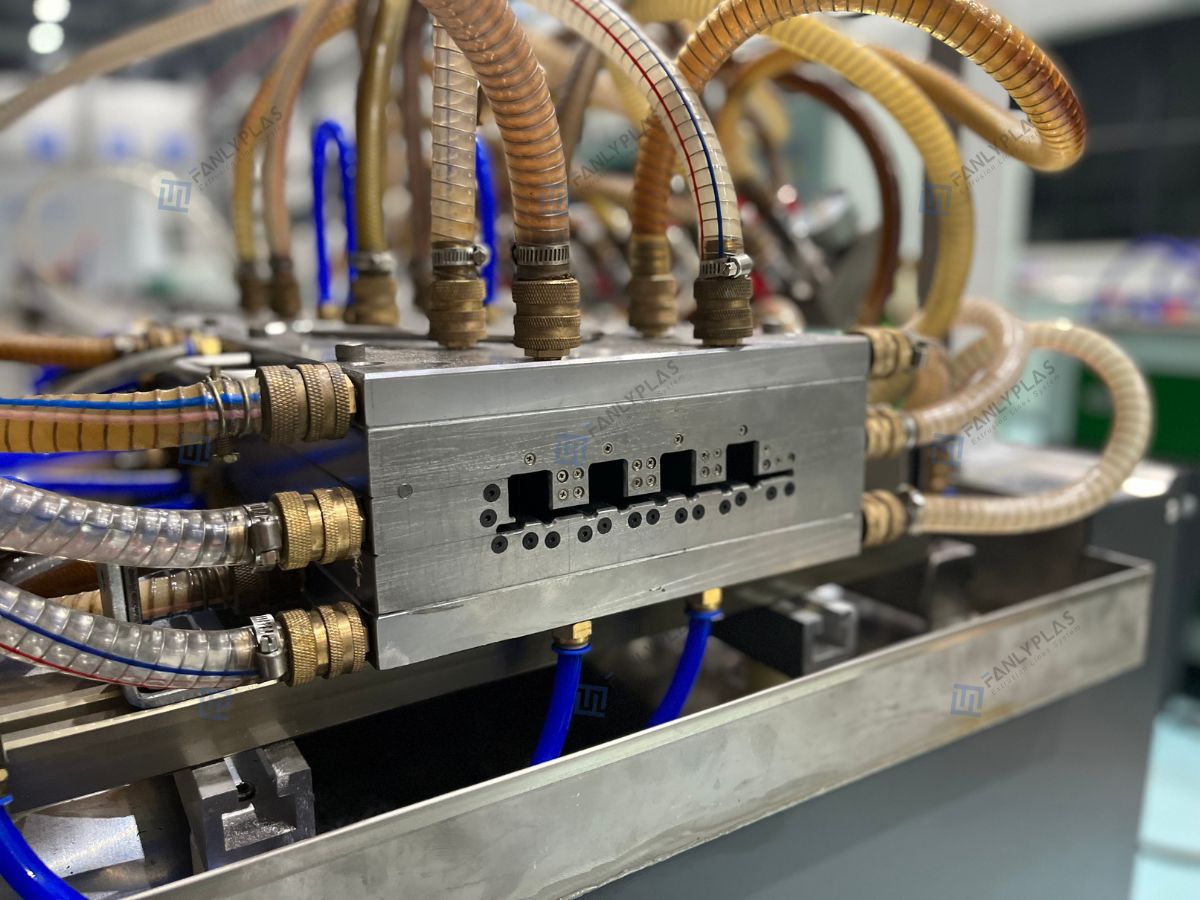

4. Molding System

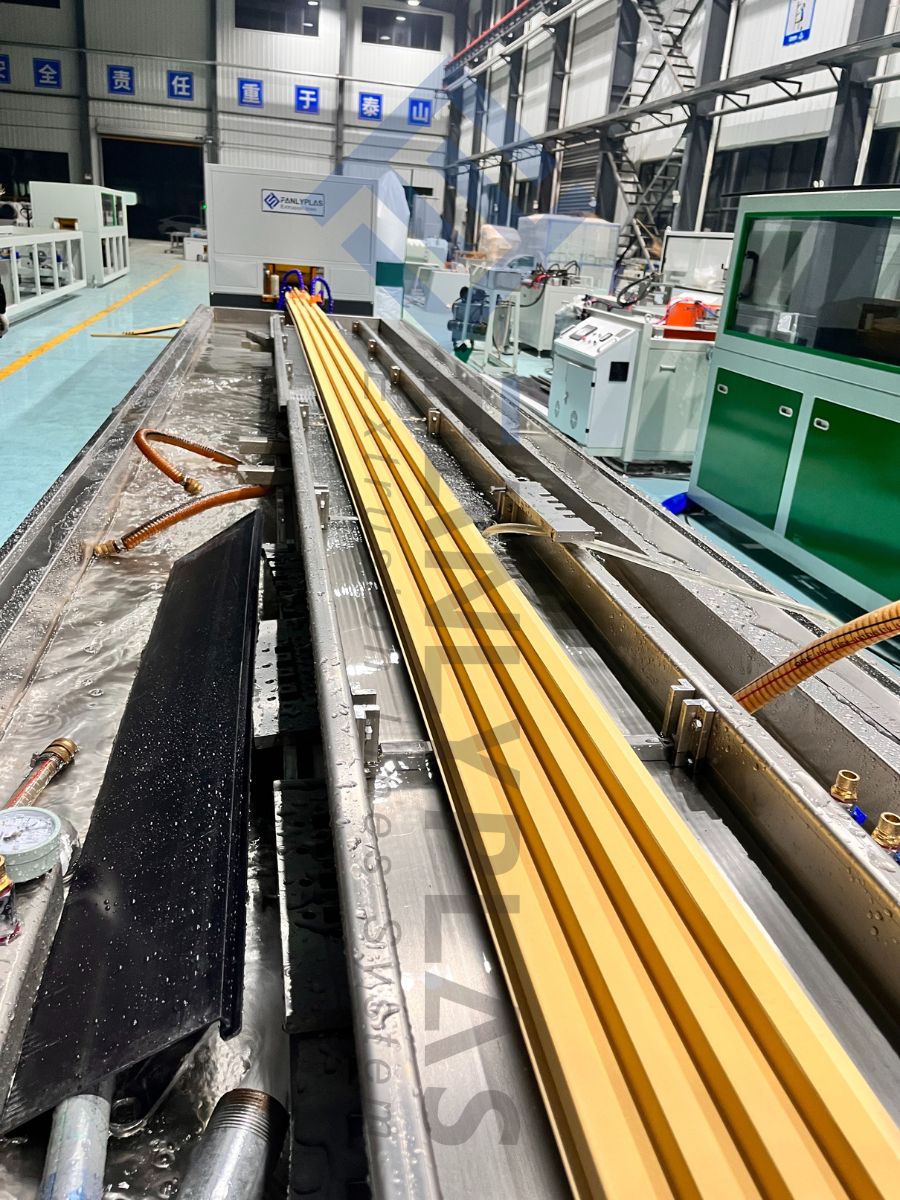

5. Calibration Table System

6. Haul off System

7. Cutter System

8. Stacker System

Production Line Workflow

1

Mixing

Put all the raw materials into the mixer, mix thoroughly in a hot pot first, and then cool in a cold pot. The final raw materials are transported to the extruder hopper through the feeder.

2

Extruder

The raw materials are directly transported to the screw barrel through the hopper, and the raw materials are plasticized by heating and pressurizing.

3

Mold

The plasticized material enters the mold, is heated and pressurized again, and obtain a flat sheet.

4

Haul off and Cutter unit

It provides strong and stable traction to the panel. When the product reaches the specified length, the cutter will automatically cut the panel and is equipped with a dust collector to reduce dust.

5

Stacker

When the set length is reached,stacker will give a signal to the cutter to cut the panel, and it will fall automatically after cutting.

WPC Indoor Louvers: Features, Applications & Process Advantages

1

2

3

Q&A

What is the production capacity of our WPC indoor louvers/wall panel production line?

What's the raw material of WPC indoor iouvers/wall panel?

What are the power requirements of the production line?

What kind of training and support do you provide for operators and maintenance staff?

If the buyer has any questions when installing the machine and using the equipment, we will provide video guidance , if necessary we will also send engineers to the buyer’s factory.

Why Choose Production Line from FANLYPLAS?

1

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality WPC indoor louvers/wall panel production line, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent WPC indoor louvers/wall panel to help you stand out in the market.

2

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

3

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known mechanical equipment production line brand from Shanghai, continuously invests in R&D to constantly optimize products and technologies. Choose us, and you will get reliable products and a long-term partnership.

Contact Us for Your Solution!

Thank you for your interest in FANLYPLAS WPC indoor louvers/wall panel production lines! If you have any questions or requirements regarding our products, or if you would like to obtain a more detailed customized solution, please fill out the contact form below with your contact information and specific needs. Our professional team will contact you as soon as possible to provide you with the best quality service and support.