WPC Decking Production Line

Be Green By Extrusion!

About FANLYPLAS WPC Decking Production Line

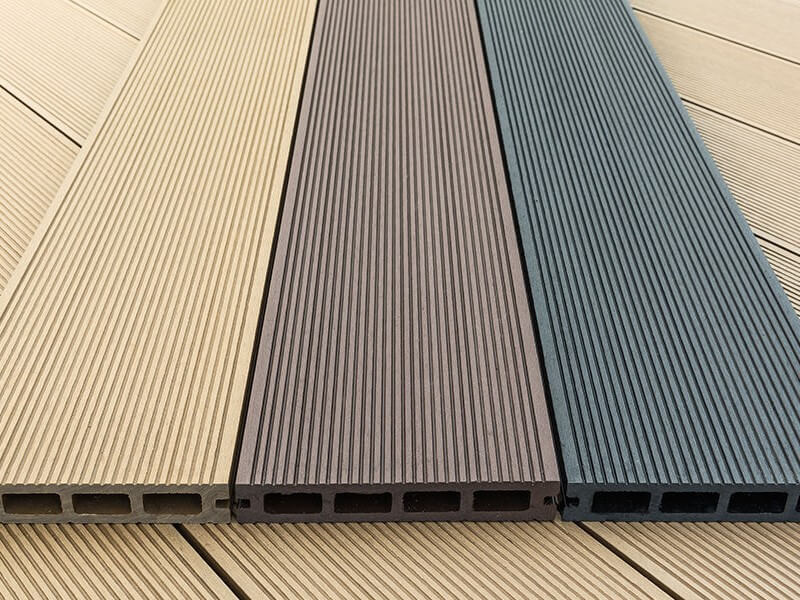

Our WPC decking production lines are engineered for versatility. We configure each line with precision conical twin-screw extruders and corresponding downstream equipment to produce a wide range of decking profiles. This includes solid core boards for maximum durability and hollow profiles for cost-effective applications. Advanced configurations support co-extrusion technology, allowing for a durable, weather-resistant cap layer over the WPC core.

The core advantage lies in our robust machinery. The main extruder features a high-torque, precision gearbox for stable operation with high wood-fill formulas. Our specialized screw design ensures optimal plasticizing and homogenous mixing of wood fiber and polymer. Paired with a PLC control system for precise temperature and speed regulation, and durable vacuum calibration tables, our lines guarantee dimensional accuracy and a superior finish on every board.

Applications of WPC Decking

WPC decking combines the natural look of wood with the resilience of polymers. It is highly resistant to moisture, rot, and insect infestation, eliminating the need for regular staining or sealing. This composite material offers excellent durability, color stability, and slip resistance, even in harsh weather conditions.

Due to its low maintenance and long lifespan, WPC decking is ideal for a wide range of outdoor applications. It is widely used for residential patios, garden platforms, and balconies. Commercially, it’s a perfect choice for marinas, public parks, swimming pool surrounds, and outdoor restaurant seating areas.

Customized WPC Decking Production Line

FANLYPLAS offers customized WPC decking production line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for WPC decking production line.

Mixer

This unit combines a high-speed heating mixer with a vertical cooling mixer. It utilizes self-friction for rapid, uniform blending of PVC resin and additives. The pot cover employs a dual-seal system, ensuring no leakage.

Conical Twin Screw Extruder

The heart of the line, this extruder features an optimized screw design for PVC dry blends. It ensures uniform plasticization and stable melt pressure. Equipped with a high-torque gearbox and advanced temperature control for high output and reliability.

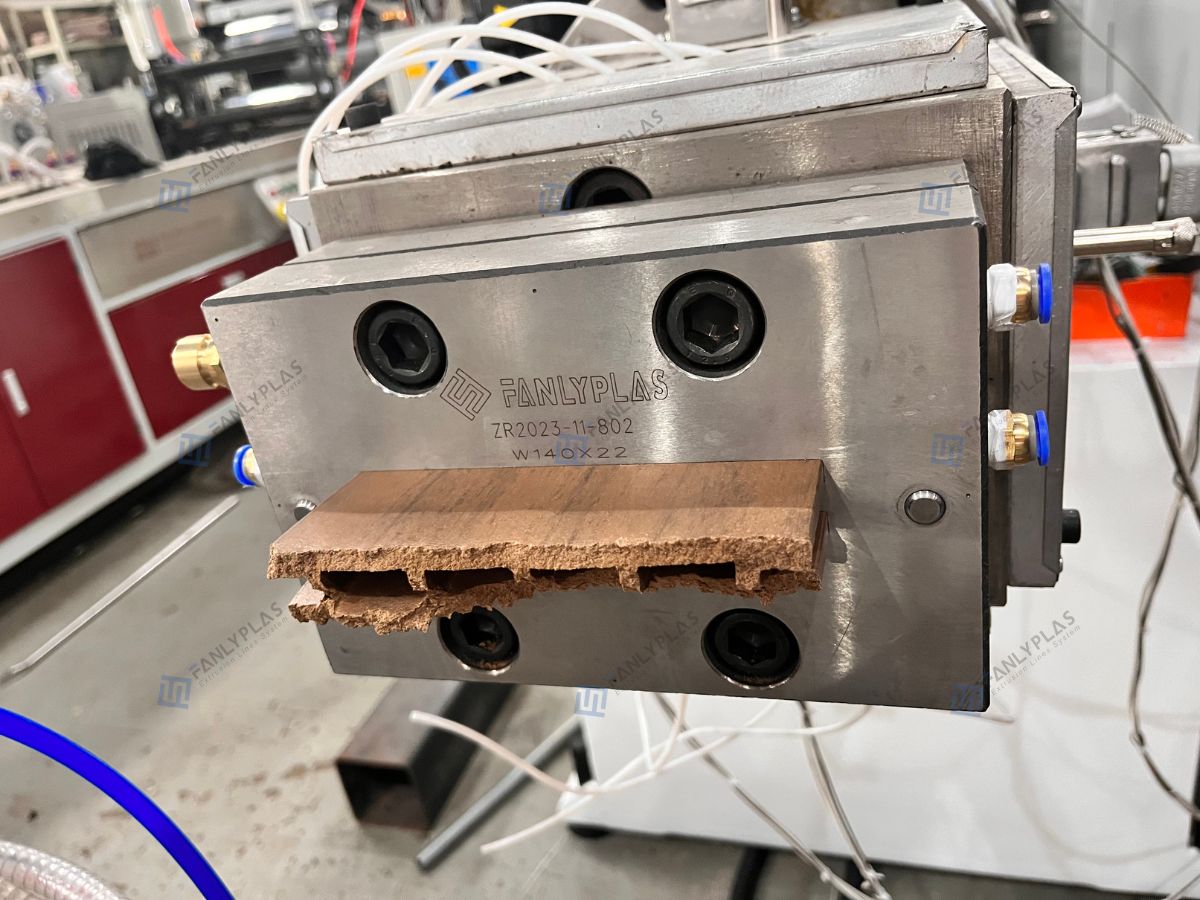

Extrusion Mold

Precision-engineered from high-quality alloy steel like 3Cr17, our molds define the final product's accuracy. The internal flow channels are meticulously designed for stable, uniform extrusion speed and feature a mirror-finish chrome plating to ensure a smooth, glossy product surface.

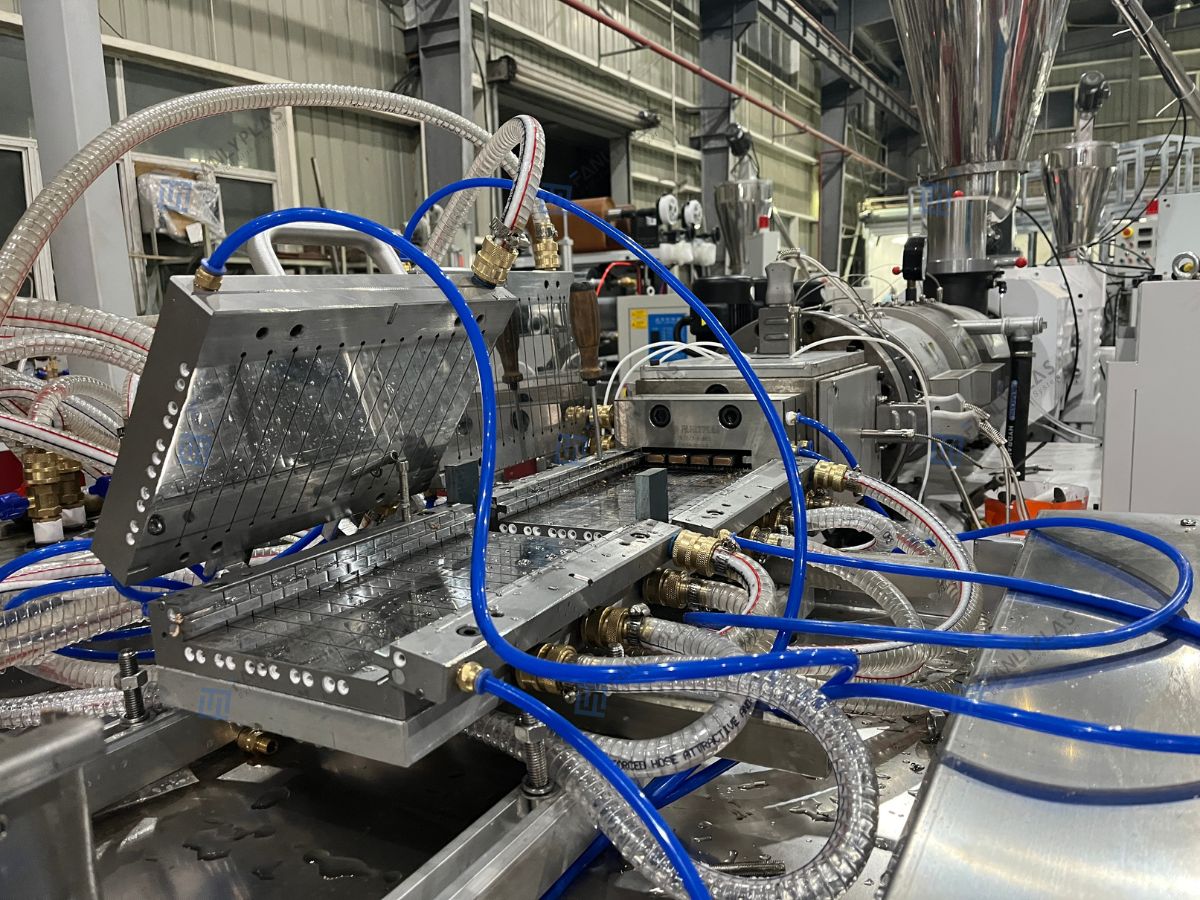

Vacuum Calibrator

Our vacuum calibrator ensures high dimensional accuracy. A powerful vacuum system presses the profile against the sizing plates, while optimized internal water channels provide rapid, uniform cooling. This process guarantees profile stability and a high-quality surface finish.

Cooling Platform System

The cooling platform provides final, stress-free solidification of the profile. Its stainless steel frame supports the extrudate, preventing deformation. A circulating water spray system efficiently removes residual core heat, ensuring complete cooling and stability.

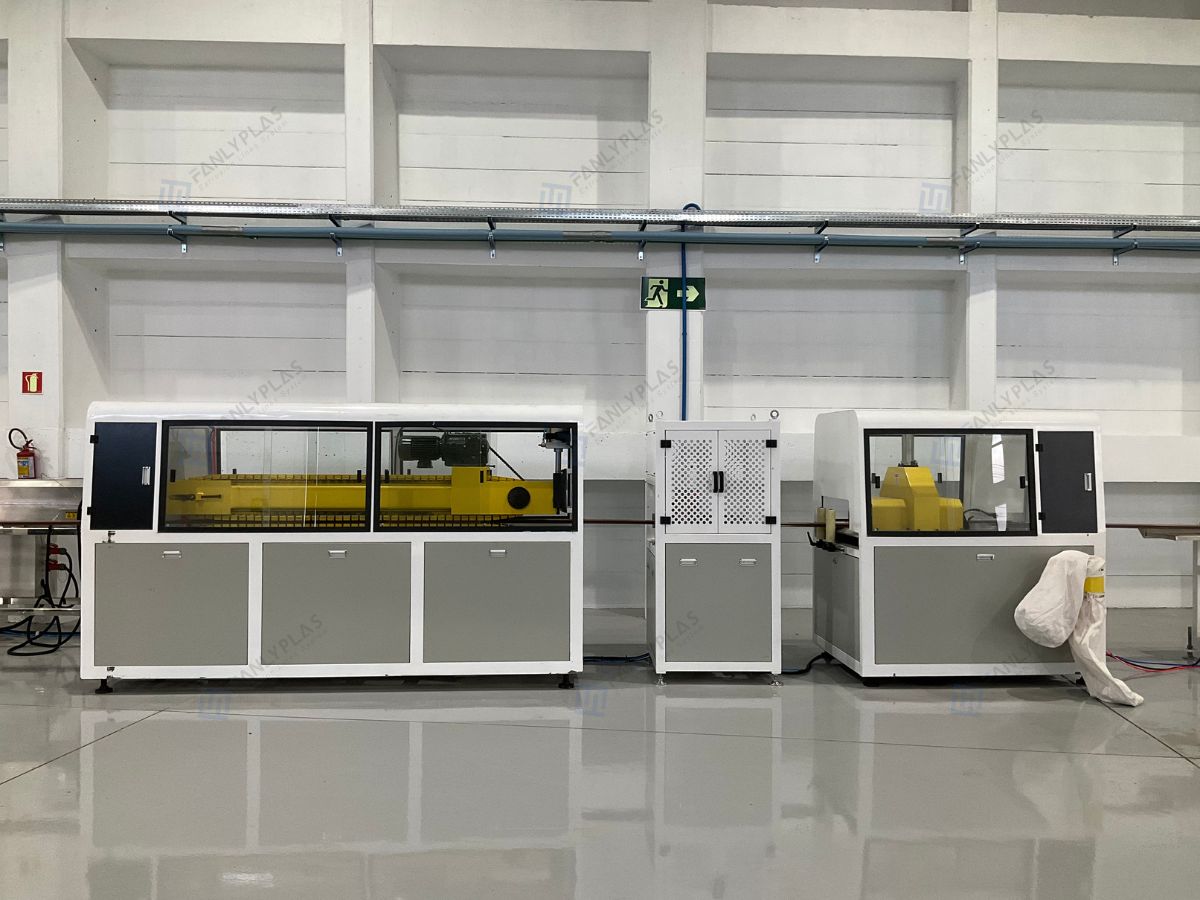

Hauling and Cutting System

The hauling system uses a caterpillar design for stable, non-slip traction, with inverter control for precise speed synchronization. The integrated saw cutter, governed by a PLC, executes clean, burr-free cuts at the exact preset length, ensuring final product accuracy.

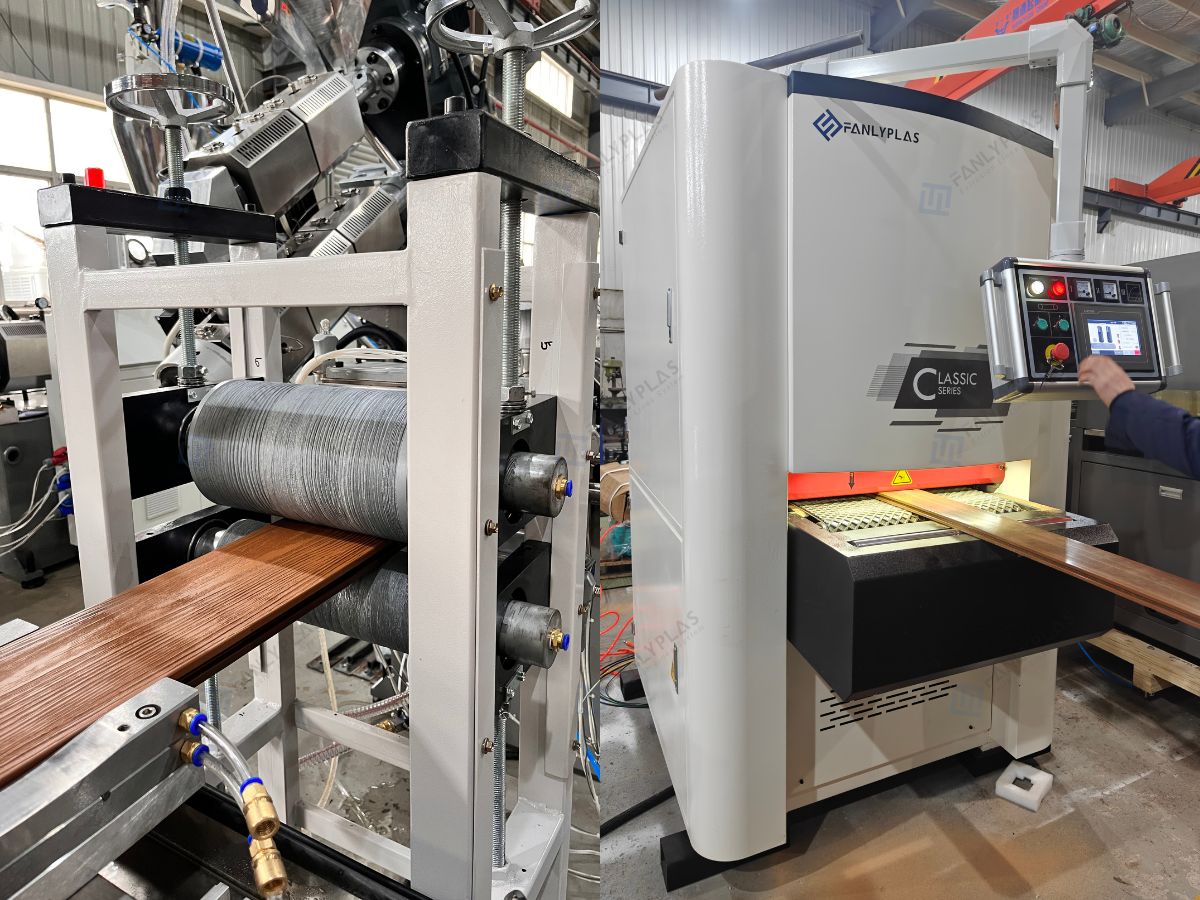

Surface Treatment System (Optional)

The in-line Embossing Machine presses deep, natural wood grain textures onto the WPC decking. The Sanding Machine polishes the surface, creating a finish that closely resembles natural wood.

Stacking System

Synchronized with the cutter, this unit automatically flips to neatly stack profiles once the set length is reached. This automated action ensures seamless collection of finished products and significantly reduces labor requirements.

Crusher and Miller

Our crusher and pulverizer system enables cost-effective, in-house recycling of scrap material. The crusher handles initial size reduction, while the high-speed pulverizer grinds the chips into a uniform fine powder, ready to be reintroduced into your production mix.

Why Choose WPC Decking Extrusion Line From FANLYPLAS?

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality WPC decking extrusion line, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent WPC decking to help you stand out in the market.

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known plastic extrusion equipment manufacturer in Shanghai, China, has obtained ISO9001 quality management system certification. Choosing us will ensure you have a long-term partner.

Q&A

What quality assurance can you offer, and what brands of components do you use?

Quality is our cornerstone. With over 20 years of manufacturing experience, we build our machines for reliability and performance. We integrate premium components from world-renowned brands like Siemens, Schneider, and Omron to guarantee stability and a long service life. Before shipment, every production line undergoes a rigorous quality control inspection and a complete test run at our factory. We welcome you or your designated third-party to witness this pre-delivery test in person to ensure your total satisfaction.

What kind of after-sales service do you provide for international customers?

We provide comprehensive global after-sales service to ensure your success. Our experienced engineers can travel to your factory for on-site installation, commissioning, and operator training. For long-term peace of mind, we offer lifetime 24/7 online technical support via video call or messaging for any troubleshooting needs. Furthermore, we guarantee a reliable, long-term supply of all necessary spare parts at a reasonable cost, ensuring your production line runs smoothly for years to come.

How can I get a quotation for your WPC decking production line?

Getting a detailed quotation is simple. Please send us your inquiry via our website’s contact form or email. To provide an accurate proposal, include your specific requirements: the type of decking profile you want to produce (hollow, solid, or co-extruded), the desired dimensions, and your target output capacity (e.g., kg/hr). Our sales engineers will then prepare a tailored technical solution and official quotation for you.

What is the delivery time for your machines?

The typical delivery time for a standard WPC decking production line is approximately 60 to 90 working days after receiving the down payment and confirming all technical specifications. The exact lead time can vary depending on the complexity and customization of the machine, as well as our current production schedule. We will provide a confirmed delivery schedule in our official sales contract.

Let's Build Your Ideal WPC Decking Production Line

Tell us your requirements, and our engineering team will provide a customized technical proposal and a competitive quote within 24 hours.