PC(polycarbonate) Sheet Extrusion Line

Be Green By Extrusion!

About FANLYPLAS PC(polycarbonate) Sheet Extrusion Line

Based in our stragtic cooperation with core components supplier and our own designs, we established a very strong system whatever in technology, machine quality stability and supplying capacity. With many successful cases we have supplied whatever in China local market or foreign market. Our PC(polycarbonate) Sheet Production line is a state-of-the-art manufacturing solution designed for producing high-quality PC(polycarbonate) sheets.Our extrusion line integrates advanced technologies to ensure excellent performance of screw designs, high efficiency, and precise control over sheet thickness and surface quality. With its reliable design and innovative features.

1.High Precision Production: The line ensures uniform thickness and consistent surface quality with advanced calibration and cooling systems.

2.Customizable Design: Flexible configuration options allow for the production of sheets in various sizes, thicknesses, and surface finishes to meet diverse industry needs.

3.Energy Efficiency: Equipped with energy-saving components, the production line reduces power consumption while maintaining high output.

4.User-Friendly Operation: Automated controls and intuitive interfaces simplify operation, minimizing labor requirements and enhancing productivity.

Applications of PC(polycarbonate) Sheets

PC(polycarbonate) sheets are known for their high impact resistance, transparency, and thermal stability. They offer excellent UV protection, flame retardancy, and are lightweight yet highly durable. PC sheets maintain clarity and strength under extreme temperatures, making them ideal for demanding applications requiring optical clarity and mechanical strength.

1.Construction: Used in roofing, skylights, and sound barriers due to its transparency and durability.

2.Automotive: Applied in headlight covers and interior panels for their lightweight and strength.

3.Electronics: Used in protective covers and components for their insulating properties.

4.Safety Equipment: Widely used in bulletproof glass and helmets for impact resistance.

Customized PC(polycarbonate) Sheet Production Line

A PC(polycarbonate) sheet production line is an integrated system, and its configuration is engineered specifically for you. We design and customize the entire line—from the extruder and T-die to the three-roll calender and downstream equipment—based on your final product’s specifications and performance goals.The following are some examples of the components of customer production lines.

Dehumidifier and dryer system

This system removes moisture from PC(polycarbonate) raw materials, effectively preventing defects like bubbles and silver streaks. The PLC controller monitors key parameters in real-time. It ensures 24/7 stable operation, seamlessly linking with the extruder for a highly efficient line.

Single Screw Extruder

According to the PC(polycarbonate) material property , a roots vented single-screw extruder is selected. The screw adopts a special mixing function and a precise temperature control system to ensure stable plasticization and no burning problem happening.

Screen Changer and Gear Pump

Our screen changer maintains melt purity by filtering contaminants. The precision gear pump then ensures constant pressure & flow for stable output. This essential synergy guarantees uniform sheet thickness, superior product quality, and continuous, highly efficient production.

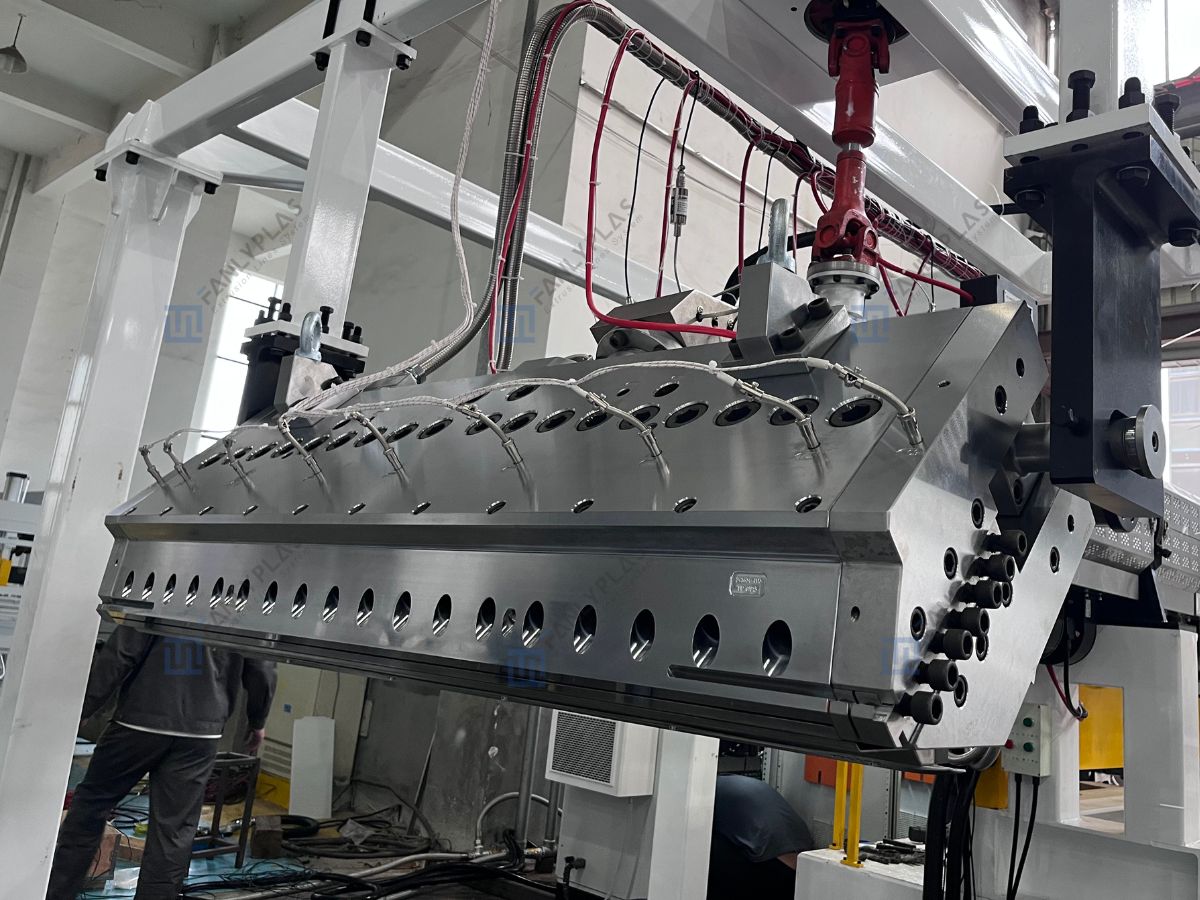

Die Head

The hanger-type die head with elastic lip which is convenient for adjusting the sheet thickness and maintain flow distribution to be uniform, and the thickness of the extruded sheet is adjusted more accurately.

Three-roll Calender

According to the thickness and glossness of the sheet, a 45° inclined three-roller calender is used. The temperature control of the three rollers is independent of each other, the gap between the rollers can be adjusted freely and have hydraulic quick openning system.

Cooling Roller Bracket

Equipped with corresponding water cooling rollers to achieve better cooling effect and avoid the sheet bending. It is also equipped with a trimming device to ensure the fixed width and edge quality of the sheet.

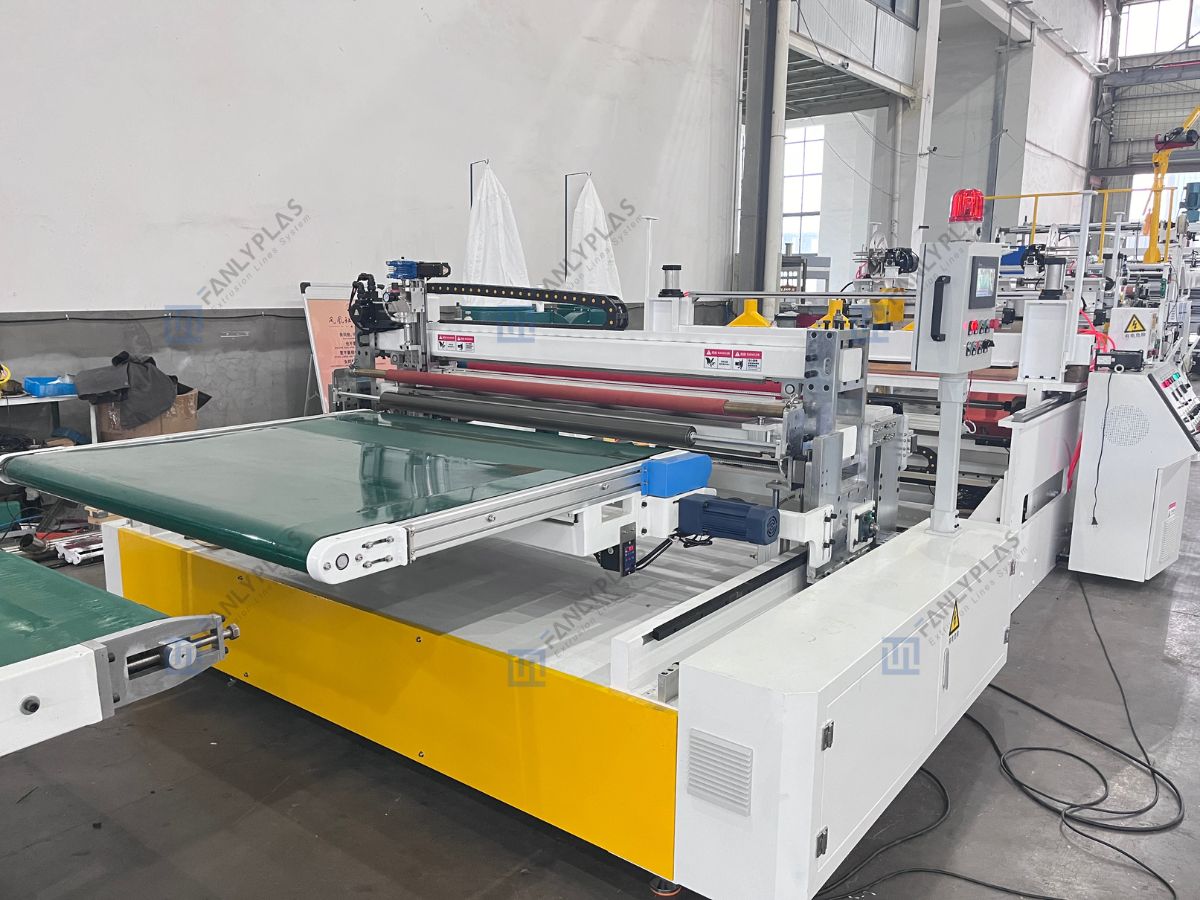

Online Laminating Machine

Our online laminating machine automatically applies protective film to acrylic sheets. Synchronized with the extrusion line, it guarantees a smooth, bubble-free finish, safeguarding the pristine surface against scratches and dust during handling and transport.

Online Edge Trimmer

Our online edge trimmer operates in sync with the production line, precisely cutting acrylic sheets to the set width during the extrusion process. Its durable blades ensure the sheet edges are smooth and clean by removing irregular trim.

Haul-Off Unit

The haul-off unit provides consistent traction to pull the sheet through the production line. Its synchronized operation with calendar ensures smooth movement and prevents deformation.

Edge Punching Collection Unit

The edge punching unit removes excess material from the sheet’s sides, providing a clean and efficient way to collect wastage materials.

Knife Cutting Machine

The knife cutting unit with top and bottom knife unit and braking unit can reach non-dust custting and be SYNC speed control with Tractor unit. It’s unique technology give the highlights of the lines.

Auto Stacking System

The stacking system organizes finished sheets for easy handling and storage. It ensures efficient stacking without scratching or damaging the surfaces. It can also reach left and right stacking which is easy for workers calculate the quantities of sheets.

Why Choose PC(polycarbonate) Sheet Extrusion Machine from FANLYPLAS?

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality PC(polycarbonate) sheet extrusion machine, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent PC(polycarbonate) sheet to help you stand out in the market.

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known plastic extrusion equipment manufacturer in Shanghai, China, has obtained ISO9001 quality management system certification. Choosing us will ensure you have a long-term partner.

Q&A

What quality assurance can you offer, and what brands of components do you use?

Quality is our cornerstone. With over 20 years of manufacturing experience, we build our machines for reliability and performance. We integrate premium components from world-renowned brands like Siemens, Schneider, and Omron to guarantee stability and a long service life. Before shipment, every production line undergoes a rigorous quality control inspection and a complete test run at our factory. We welcome you or your designated third-party to witness this pre-delivery test in person to ensure your total satisfaction.

What kind of after-sales service do you provide for international customers?

We provide comprehensive global after-sales service to ensure your success. Our experienced engineers can travel to your factory for on-site installation, commissioning, and operator training. For long-term peace of mind, we offer lifetime 24/7 online technical support via video call or messaging for any troubleshooting needs. Furthermore, we guarantee a reliable, long-term supply of all necessary spare parts at a reasonable cost, ensuring your production line runs smoothly for years to come.

How can I get a quotation for your polycarbonate(PC) sheet production line?

To receive an accurate quotation, please contact us with your specific requirements, as our production lines are fully customizable. Provide us with details such as your desired sheet width and thickness, required output capacity (kg/hr), and the intended end application. Also, mention any special requests like specific component brands. Once we have this information, our sales engineering team will promptly prepare and send you a detailed technical proposal and a competitive price quotation.

What is the delivery time for your extruders?

The typical delivery time for a standard polycarbonate(PC) sheet extrusion Line is approximately 60 to 90 working days after receiving the down payment and confirming all technical specifications. The exact lead time can vary depending on the complexity and customization of the machine, as well as our current production schedule. We will provide a confirmed delivery schedule in our official sales contract.

Let's Build Your Ideal PC(polycarbonate) Sheet Extrusion Line

Tell us your requirements, and our engineering team will provide a customized technical proposal and a competitive quote within 24 hours.