HIPS Sheet Extrusion Line

Be Green By Extrusion!

About FANLYPLAS HIPS Sheet Extrusion Line

Our HIPS sheet extrusion lines are engineered for flexibility, capable of producing both single-layer and multi-layer co-extruded sheets to meet diverse market demands. This versatility allows for the manufacturing of high-quality sheets for thermoforming, packaging, and industrial applications. The line can be configured to produce sheets with varied characteristics, such as high-gloss surfaces (HIPS/GPPS co-extrusion) or specific protective layers.

Our advantage lies in precision and reliability. A high-efficiency extruder provides stable melt flow, while the high-precision T-die and three-roll calender guarantee uniform thickness and a superior surface finish. The entire line is managed by an integrated PLC control system for simple, automated operation. Key components are optimized for energy efficiency, ensuring stable, long-term production with reduced operational costs and delivering a final product of the highest

Applications of HIPS Sheets

High Impact Polystyrene (HIPS) is a versatile and cost-effective thermoplastic material known for its excellent impact resistance, making it significantly tougher than standard polystyrene. A key characteristic is its outstanding thermoformability, allowing it to be easily molded into intricate designs with deep draws while retaining structural integrity. The material features a smooth, matte surface that is ideal for high-quality printing, painting, and gluing, making it perfect for branded products.

These properties make HIPS sheet a preferred choice across numerous industries. In packaging, it is widely used for dairy containers (yogurt cups), food trays, disposable lids, and consumer goods clamshells. It is also a primary material for refrigerator liners and internal components in the appliance industry. Furthermore, its excellent printability makes it ideal for point-of-purchase (POP) displays, signage, and promotional items, showcasing its broad market appeal.

Customized HIPS Sheet Extrusion Line

A HIPS sheet extrusion line is an integrated system, and its configuration is engineered specifically for you. We design and customize the entire line—from the extruder and T-die to the three-roll calender and downstream equipment—based on your final product’s specifications and performance goals.The following are some examples of the components of customer production lines.

Dehumidifier and dryer system

Considering the HIPS easy absorbing moisture, we will do pre-treatment of chemicals granule before extrusion process, then combine loading system to support stable feeding material to extruder.

Extruder

The extruder melts and mixes the raw materials under high temperature and pressure. Using a screw system, it ensures uniform plasticization and homogeneity of the HIPS blend, which is critical for high-quality sheets.

T-Die

The die head shapes the melted material into a flat sheet. It ensures precise control over the sheet’s width and thickness. High-quality die heads contribute to uniform sheet dimensions and smooth surfaces.

Three-Roller Calender

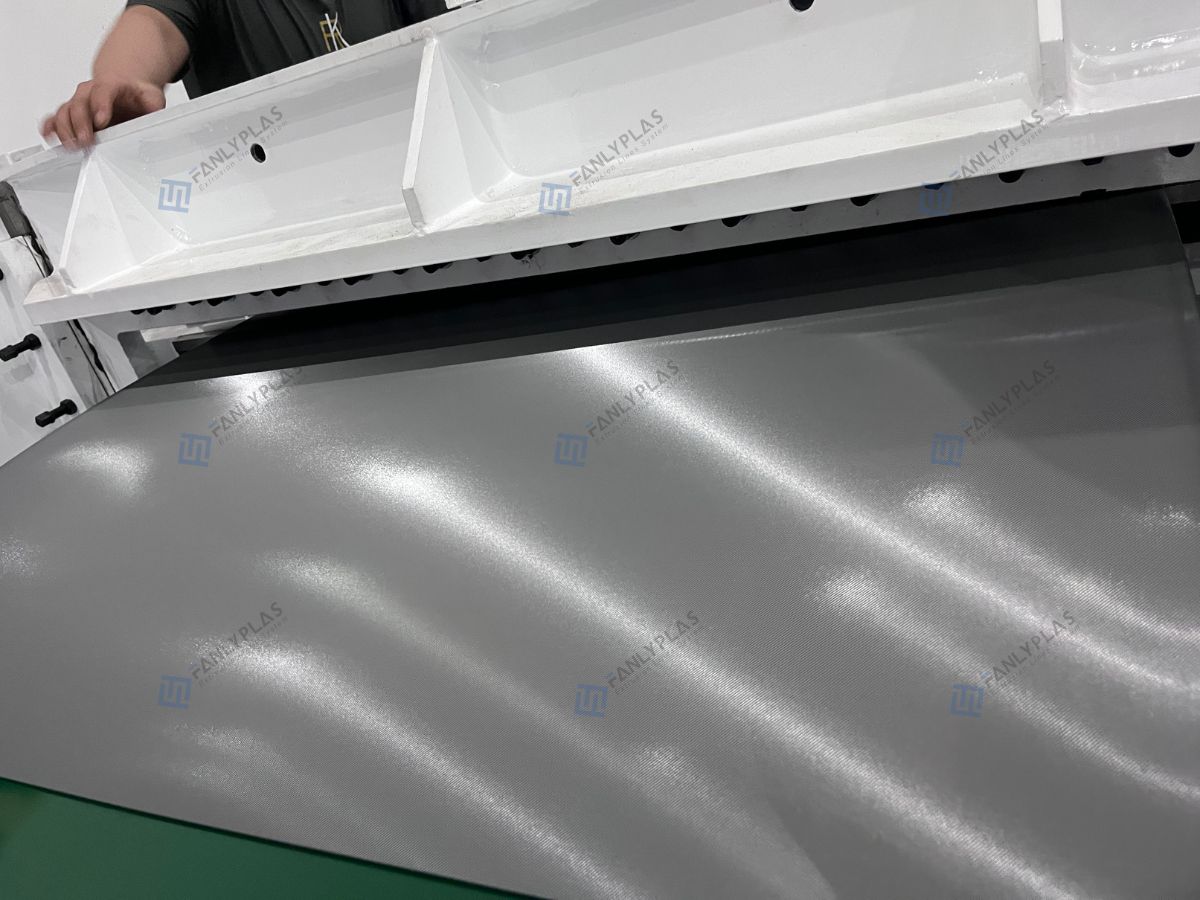

The three-roller calender further refines the sheet by pressing it between three rollers to achieve the desired thickness and surface finish. It also enhances sheet uniformity and eliminates air bubbles.

Lamination Unit Platform

The lamination platform applies a decorative film to the surface of the sheet. This process enhances the sheet’s appearance and adds specific properties such as colorful designs and glossy designs.

Cooling Bracket

The cooling bracket is used to cool the extruded sheet gradually, ensuring dimensional stability and preventing warping. It typically uses air or water cooling systems for uniform cooling.

Tractor

The tractor pulls the sheet through the production line at a controlled speed. It ensures steady tension, preventing deformation and maintaining uniform sheet quality.

Cutting Machine

The cutting machine precisely cuts the sheet into desired lengths. It offers flexibility to produce sheets of various sizes and ensures clean, burr-free edges.

Why Choose HIPS Sheet Machine from FANLYPLAS?

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality HIPS sheet machine, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent HIPS sheet to help you stand out in the market.

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known plastic extrusion equipment manufacturer in Shanghai, China, has obtained ISO9001 quality management system certification. Choosing us will ensure you have a long-term partner.

Q&A

What quality assurance can you offer, and what brands of components do you use?

Quality is our cornerstone. With over 20 years of manufacturing experience, we build our machines for reliability and performance. We integrate premium components from world-renowned brands like Siemens, Schneider, and Omron to guarantee stability and a long service life. Before shipment, every production line undergoes a rigorous quality control inspection and a complete test run at our factory. We welcome you or your designated third-party to witness this pre-delivery test in person to ensure your total satisfaction.

What kind of after-sales service do you provide for international customers?

We provide comprehensive global after-sales service to ensure your success. Our experienced engineers can travel to your factory for on-site installation, commissioning, and operator training. For long-term peace of mind, we offer lifetime 24/7 online technical support via video call or messaging for any troubleshooting needs. Furthermore, we guarantee a reliable, long-term supply of all necessary spare parts at a reasonable cost, ensuring your production line runs smoothly for years to come.

How can I get a quotation for your HIPS sheet production line?

To receive an accurate quotation, please contact us with your specific requirements, as our production lines are fully customizable. Provide us with details such as your desired sheet width and thickness, required output capacity (kg/hr), and the intended end application. Also, mention any special requests like specific component brands. Once we have this information, our sales engineering team will promptly prepare and send you a detailed technical proposal and a competitive price quotation.

What is the delivery time for your machines?

The typical delivery time for a standard HIPS sheet production line is approximately 60 to 90 working days after receiving the down payment and confirming all technical specifications. The exact lead time can vary depending on the complexity and customization of the machine, as well as our current production schedule. We will provide a confirmed delivery schedule in our official sales contract.

Let's Build Your Ideal HIPS Sheet Extrusion Line

Tell us your requirements, and our engineering team will provide a customized technical proposal and a competitive quote within 24 hours.