PP Sheet Extrusion Line

Be Green By Extrusion!

About FANLYPLAS PP Sheet Extrusion Line

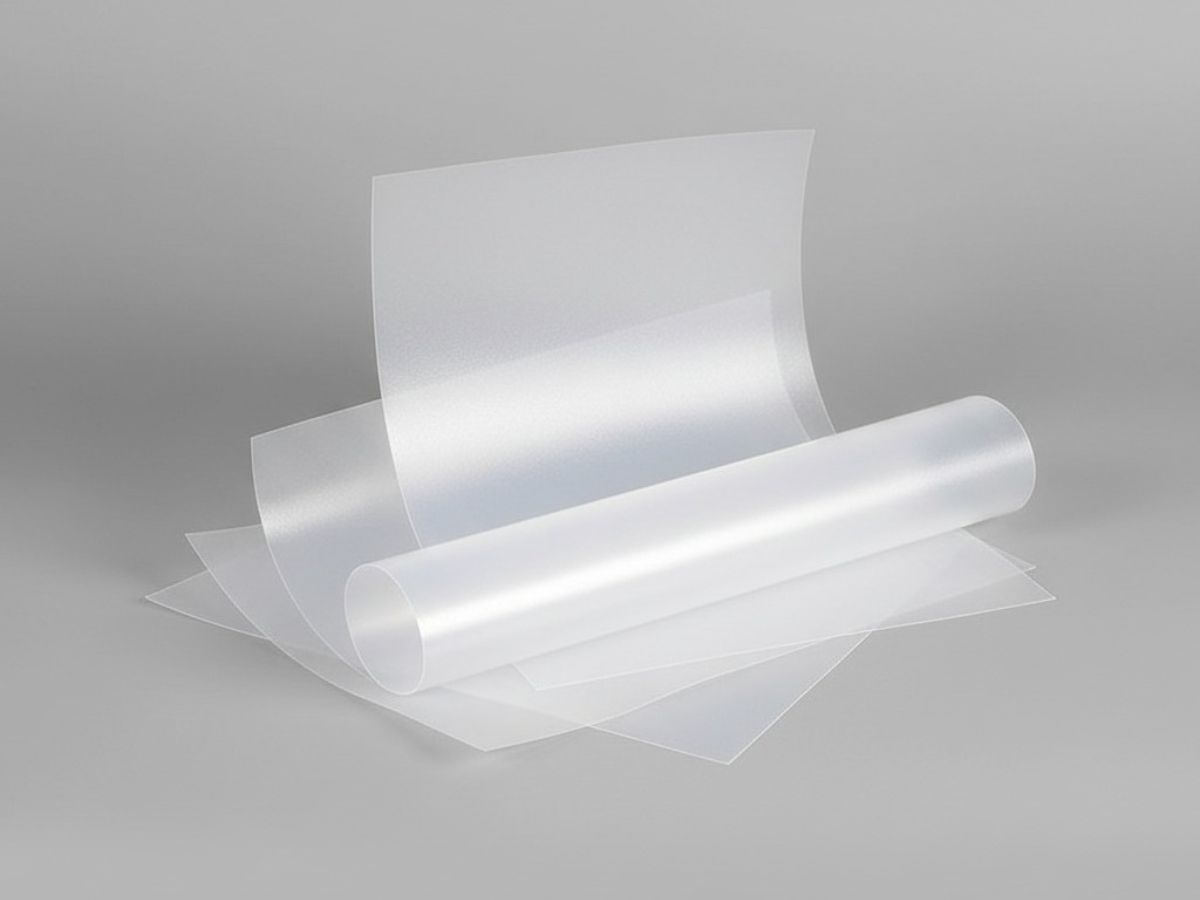

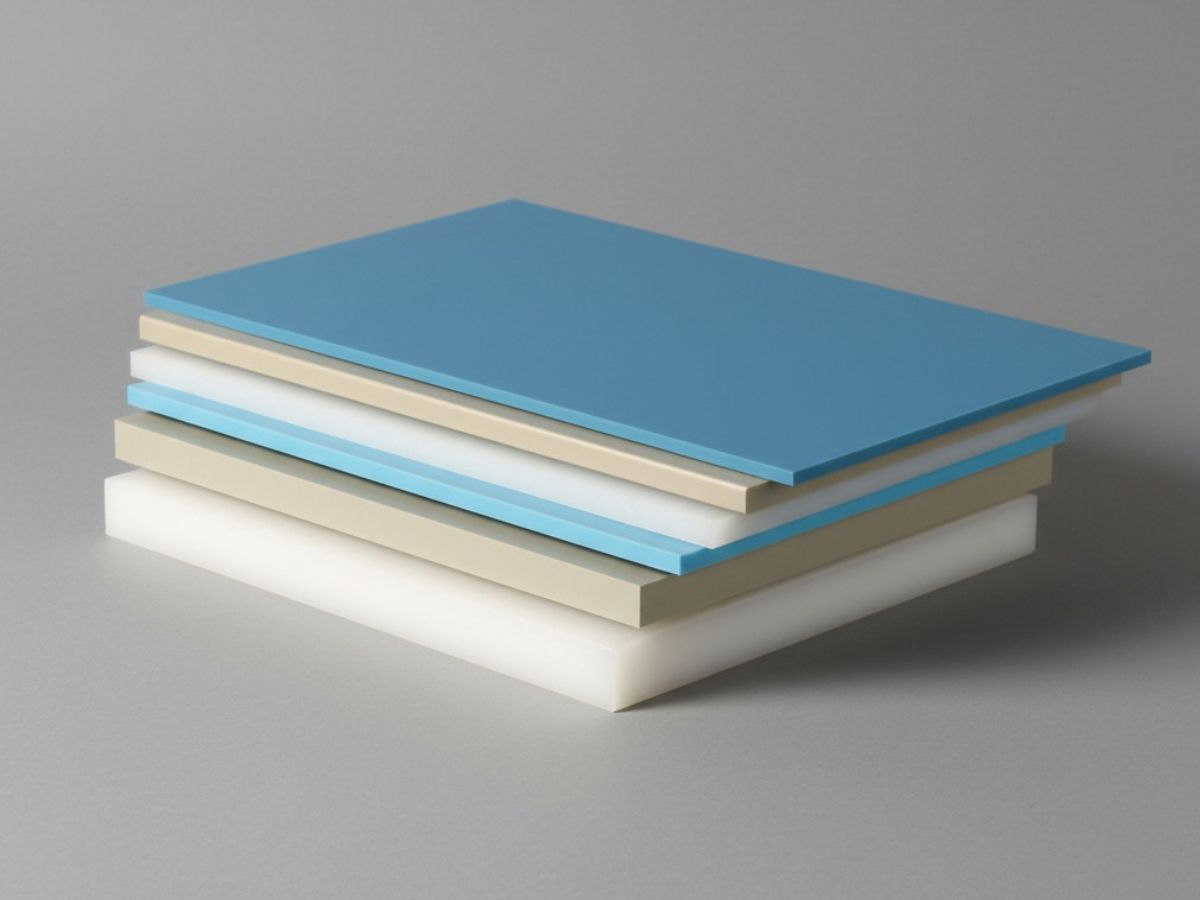

Our PP Sheet Extrusion Line is engineered for energy efficiency and high performance, producing top-quality polypropylene (PP) sheets. These sheets are known for their exceptional chemical resistance, thermal stability, and mechanical strength, making them ideal for applications in industries such as food and electronic packaging, agriculture, and medicine.

Our equipment is capable of producing single-layer PP sheets using a single extruder, three-layer sheets with a dual extruder, and multi-layer sheets through a co-extrusion process with multiple extruders. We can create PP sheets in a variety of thicknesses and colors, such as white, black, and transparent. We also provide a wide range of customizable options to meet your unique production requirements.

Applications of PP Sheets

Food packaging : PP sheets are non-toxic and safe and can be used to make various food containers, trays and lids, especially for microwaveable packaging.

Stationery and gift boxes : Transparent or colored PP sheets can be used to make file boxes, folders, gift boxes and other stationery products.

Interior decoration : PP sheets can be used to make ceilings, partition walls, billboards and display racks. They are light and easy to install.

Chemical Equipment : Can be used to make various corrosion-resistant chemical containers, storage tanks and work surfaces.

Automotive Industry : PP sheets are often used to make automotive interior parts such as door panels, instrument panels, and battery trays due to their lightness and impact resistance.

Advertising and printing : PP sheet has a smooth surface and is suitable for printing. It is used to make billboards, signs and posters.

PP sheets can be found everywhere in our daily lives, including insulation materials and casings for electronic appliances, storage boxes, trash cans, and various kitchen supplies.

Customized PP sheet extrusion line

A PP sheet extrusion line is an integrated system, and its configuration is engineered specifically for you. We design and customize the entire line—from the extruder and T-die to the three-roll calender and downstream equipment—based on your final product’s specifications and performance goals. This bespoke approach ensures your production line is the perfect fit for your application, delivering maximum efficiency and superior quality.

Mixer

Engineered for optimal material prep, our high-speed mixer guarantees a homogeneous blend of PP resin and additives. Its rapid, uniform dispersion is the key to achieving superior sheet quality, vibrant color consistency, and reliable end-product performance.

Extruder

Our single-screw extruder has an optimized screw geometry for efficient PP plasticizing and high melt homogeneity. Its multi-zone barrel heating and cooling provides precise thermal control, delivering stable melt pressure and consistent output for superior sheet quality.

Die-Head

Our high-precision T-die utilizes a "clothes hanger" flow channel design for superior melt distribution. Finely adjustable die lips, coupled with multi-zone internal heating, allow for precise gauge control, ensuring exceptional sheet flatness and thickness consistency.

Three-Roll Calender

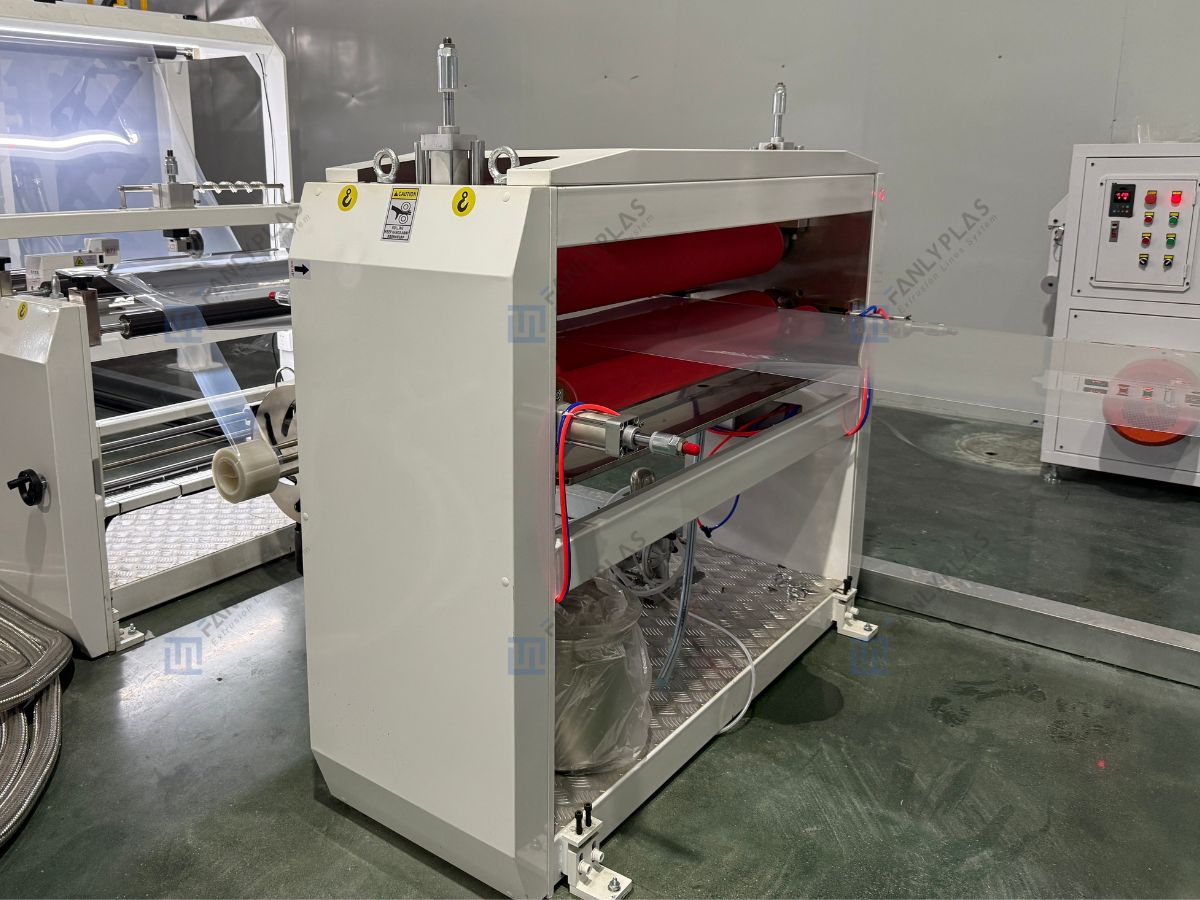

This unit features three independently driven, chrome-plated rollers with precise gap control. An internal roller heating system maintains uniform surface temperatures, ensuring optimal sheet cooling, glazing, and embossing for a high-quality, consistent surface finish.

Edge Trimming Machine

Equipped with high-hardness circular blades, this unit performs precise, continuous edge trimming. The cutting width is easily adjustable to meet final product specifications, ensuring clean, burr-free edges and exact dimensional accuracy for the finished sheet.

Oiling Machine

Primarily applies a micro-thin anti-adhesion agent, preventing sheet blocking during winding. This coating also acts as a lubricant within the calibrator to reduce friction and buildup, while enhancing the final sheet's surface gloss and downstream processability.

Dryer

This dryer rapidly sets the applied anti-adhesion agent. It uses forced hot air to evaporate carriers, instantly forming a stable, solid film. This process ensures immediate anti-blocking for winding and prevents oil spots for a flawless surface finish.

Haul-off Machine

Driven by an inverter-controlled motor, our haul-off unit provides constant, stable traction. Its large-diameter, rubber-coated rollers ensure a non-slip grip, precisely controlling the pull speed to guarantee consistent sheet thickness and dimensional stability.

Winding Platform

Our winder utilizes a precision torque motor for constant tension control throughout the winding cycle. This ensures tightly wound, uniform rolls without deformation. The dual-station design allows for rapid roll changes, maximizing production uptime and efficiency.

Why Choose PP Sheet Extruder From FANLYPLAS?

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality PP sheet extruder, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent PP sheet to help you stand out in the market.

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known plastic extrusion equipment manufacturer in Shanghai, China, has obtained ISO9001 quality management system certification. Choosing us will ensure you have a long-term partner.

Q&A

What quality assurance can you offer, and what brands of components do you use?

Quality is our cornerstone. With over 20 years of manufacturing experience, we build our machines for reliability and performance. We integrate premium components from world-renowned brands like Siemens, Schneider, and Omron to guarantee stability and a long service life. Before shipment, every production line undergoes a rigorous quality control inspection and a complete test run at our factory. We welcome you or your designated third-party to witness this pre-delivery test in person to ensure your total satisfaction.

What kind of after-sales service do you provide for international customers?

We provide comprehensive global after-sales service to ensure your success. Our experienced engineers can travel to your factory for on-site installation, commissioning, and operator training. For long-term peace of mind, we offer lifetime 24/7 online technical support via video call or messaging for any troubleshooting needs. Furthermore, we guarantee a reliable, long-term supply of all necessary spare parts at a reasonable cost, ensuring your production line runs smoothly for years to come.

How can I get a quotation for your PP sheet production line?

To receive an accurate quotation, please contact us with your specific requirements, as our production lines are fully customizable. Provide us with details such as your desired sheet width and thickness, required output capacity (kg/hr), and the intended end application. Also, mention any special requests like specific component brands. Once we have this information, our sales engineering team will promptly prepare and send you a detailed technical proposal and a competitive price quotation.

What is the delivery time for your PP sheet extrusion machines?

The typical delivery time for a standard PP sheet extrusion machine is approximately 60 to 90 working days after receiving the down payment and confirming all technical specifications. The exact lead time can vary depending on the complexity and customization of the machine, as well as our current production schedule. We will provide a confirmed delivery schedule in our official sales contract.

Let's Build Your Ideal PP Sheet Extrusion Line

Tell us your requirements, and our engineering team will provide a customized technical proposal and a competitive quote within 24 hours.