PVC Edge Banding Extrusion Line

Be Green By Extrusion!

About FANLYPLAS PVC Edge Banding Extrusion Line

PVC/ABS edge banding extrusion can be divided into two categories according to the production process: edge banding sheet production line and edge banding strip production line.

1. Edge banding sheet production process:

Edge banding sheet is extruded by a twin-screw extruder, through a sheet die, a three-roller calendar, haul-off, cooling, and winding. Then slit the sheet into strips.

It is suitable for producing single-size products with high output demand, which can increase output and save manpower.

2. There are two production processes for strip edge banding:

(1) One-step method for powder: twin-screw extrusion production line.

This process is simple and convenient, reducing costs.

(2) Two-step method for pellets:

– Twin-screw granulation production line

– Single-screw extrusion production line

This process has a better plasticization effect on raw materials and higher product quality.

We recommend the most suitable production line for you according to your needs and provide the most cost-effective solution.

Applications of PVC Edge Banding

PVC edge banding is favored for its durability and cost-effectiveness. It exhibits excellent mechanical strength and chemical resistance, capable of withstanding common moisture and chemicals found in kitchen and bathroom environments. PVC edge bands come in a variety of colors, allowing precise matching with different furniture styles and colors. Moreover, this material is easy to process and install, readily applied to various board edges through heat transfer or adhesive methods. PVC edge bands offer an economical choice to enhance furniture aesthetics and extend lifespan.

1.Furniture Industry: PVC edge bands are extensively used in office furniture, kitchen cabinets, and wardrobes for edge finishing, providing excellent visual appeal and physical protection.

2.Construction and Decoration: Suitable for edging door frames, window frames, and interior decorative strips, enhancing the durability and aesthetics of architectural elements.

3.Commercial Facilities: Used in shop decorations and commercial display cases, ensuring neat and durable edges, enhancing the overall aesthetics of commercial spaces.

4.Vehicle Interiors: Employed in the interior decorations of vehicles, such as in cars and motorhomes, offering additional abrasion resistance along the edges.

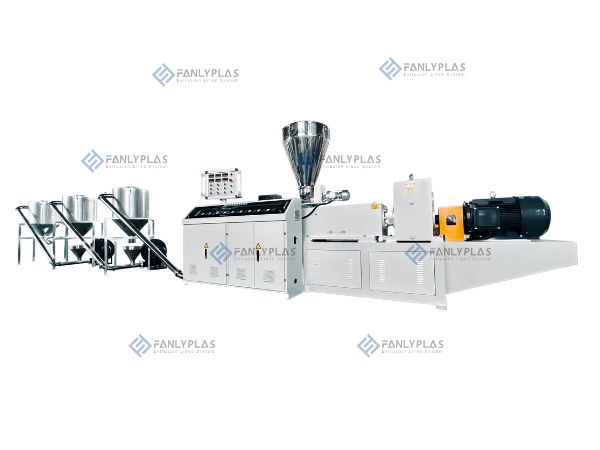

Equipment composition of Edge Banding Sheet Production Line

Extruder

Adopt Φ65/132mm conical twin-screw exhaust extruder. Improve production efficiency, product quality, and output. Ensure stable, safe, and environmentally friendly running.

Mould

The hanger-type runner mould reduces manual operation, reduces costs, avoids mold adhesion and damage problems; improves production efficiency; and ensures product accuracy.

Three-Roller Calender

According to the product thickness and material characteristics, adopt vertical three-roller calender. The gap between the rollers can be freely adjusted, combining electric and manual operation.

Cooling Bracket

Equipped with upper and lower disc cutter side trimming devices. Adopt inverter control. The cooling and haul-off can be adjusted separately or synchronously.

Double station Winder

Driven by torque motor, controlled by tension controller, with deviation correction mechanism and unloading and material return mechanism.

Sheet Slitting Machine

PLC controls the tension of winding and rewinding. Equipped with photoelectric deviation correction and metering function.

Equipment composition of Edge Banding Strip Production Line

Granulation Production Line

The Conical twin-screw granulation extruder turns powder into granules. Laying a good plasticization foundation for high-quality products extruded by single screw extruder.

Extrusion Line

Divided into two types. Single screw extruder is suitable for granules, and twin screw extruder is suitable for powders. According to the product size, single-cavity, double-cavity, and four-cavity production lines can be realized.

Extruder

Adopts permanent magnet motor, high efficiency, stable running, energy saving, and low maintenance cost. High plasticizing screw structure, suitable for different raw material ratio formulas.

Water Tank With Embossing System

Combined with online embossing unit, equipped with vacuum system to meet the needs of high-quality products using calibrator.

Haul-off and Primer Coating

Adopt vacuum primer injection technology strictly control primer quantity and reduce waste, sealed environment, no irritating odor.

Automatic Winder Machine

Automatic winding and cutting, accurate metering, and reduced labor.

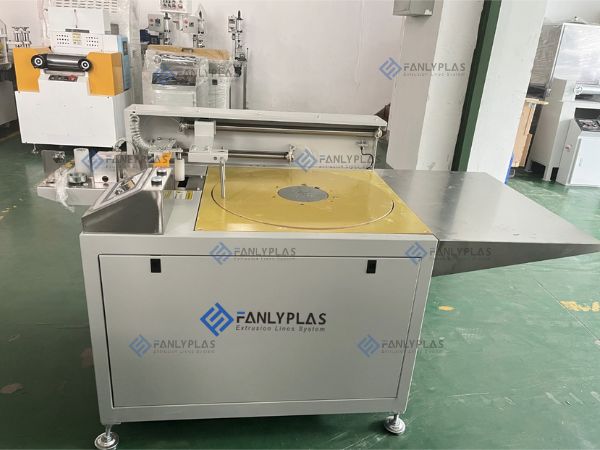

Off-line Embossing Machine

Meet the needs of deep embossing and post-printing embossing, can emboss 4 edge bands at the same time. Oil heating, have high production efficiency and good pattern effect.

Online Size Detection System

Online self-detection of product width and feedback signal to the extruder to ensure stable production line running and product accuracy.

Why Choose PVC Edge Banding Production Line from FANLYPLAS?

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality PVC edge banding production line, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent PVC edge banding to help you stand out in the market.

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known plastic extrusion equipment manufacturer in Shanghai, China, has obtained ISO9001 quality management system certification. Choosing us will ensure you have a long-term partner.

Q&A

What quality assurance can you offer, and what brands of components do you use?

Quality is our cornerstone. With over 20 years of manufacturing experience, we build our machines for reliability and performance. We integrate premium components from world-renowned brands like Siemens, Schneider, and Omron to guarantee stability and a long service life. Before shipment, every production line undergoes a rigorous quality control inspection and a complete test run at our factory. We welcome you or your designated third-party to witness this pre-delivery test in person to ensure your total satisfaction.

What kind of after-sales service do you provide for international customers?

We provide comprehensive global after-sales service to ensure your success. Our experienced engineers can travel to your factory for on-site installation, commissioning, and operator training. For long-term peace of mind, we offer lifetime 24/7 online technical support via video call or messaging for any troubleshooting needs. Furthermore, we guarantee a reliable, long-term supply of all necessary spare parts at a reasonable cost, ensuring your production line runs smoothly for years to come.

How can I get a quotation for your PVC edge banding production line?

Getting a detailed quotation is easy. Please send your inquiry to our email at [export@fanlyplas.com] or fill out the contact form on our website. To help us provide an accurate quote, please include your specific requirements, such as the desired output capacity (kg/h), the edge banding width and thickness, and any other technical needs. Our sales team will respond within 24 hours.

What is the delivery time for your machines?

The typical delivery time for a standard PVC edge banding production line is approximately 60 to 90 working days after receiving the down payment and confirming all technical specifications. The exact lead time can vary depending on the complexity and customization of the machine, as well as our current production schedule. We will provide a confirmed delivery schedule in our official sales contract.

What is the difference between the sheet edge banding extrusion line and the profile edge banding extrusion line? How to choose?

The product sizes and outputs are different. The sheet line is suitable for producing edge banding with a large output of single-specification products, with a size range of 0.4-1.2mm thick and a width greater than 250mm. The strip line is suitable for producing product sizes: 0.4-2mm thick and 22-55mm wide.

Can the production line produce edge banding of different sizes, thicknesses and patterns?

It can be achieved by changing the molds and embossing rollers of different sizes.

Let's Build Your Ideal PVC Edge Banding Production Line

Tell us your requirements, and our engineering team will provide a customized technical proposal and a competitive quote within 24 hours.