PVC Profile Extrusion Line

Be Green By Extrusion!

About FANLYPLAS PVC Profile Extrusion Line

Our PVC profile extrusion line is a powerhouse of versatility, engineered to serve diverse industrial sectors. Its core capability lies in producing a wide spectrum of profiles, from complex, multi-cavity architectural elements to high-precision channels for electronics. The system’s adaptability allows you to manufacture custom shapes and sizes, meeting specific client requirements for both aesthetic and functional parts with high precision.

Engineered for superior output, our line’s conical twin-screw extruder ensures optimal melt homogeneity for complex geometries. The integrated Siemens PLC system provides centralized control over temperature, speed, and downstream equipment for consistent production quality. High-efficiency vacuum calibration and cooling systems guarantee dimensional accuracy, while robust construction minimizes vibration and ensures long-term operational stability.

Applications of PVC Profiles

PVC profiles produced with our machinery exhibit exceptional characteristics. They offer excellent thermal and acoustic insulation, contributing to energy-efficient buildings. Their inherent resistance to moisture, chemicals, and UV radiation ensures long-term durability and color stability with minimal maintenance. Furthermore, PVC is inherently flame-retardant, adding a critical layer of safety to any application.

The superior features of PVC profiles make them the material of choice across multiple sectors. In construction, they are essential for windows, doors, wall cladding, and rainwater systems. In interior design, they are used for decorative moldings, skirting boards, and ceiling panels. Their electrical insulation properties also make them ideal for cable conduits and trunking systems in both commercial and residential projects.

Customized PVC Profile Production Line

FANLYPLAS offers customized PVC profile production line based on customer requirements, including product specifications, production volume, facility size, and desired level of automation. We provide flexible configurations to meet various needs. Below are some of the standard configurations available for PVC profile production line.

Conical Twin-Screw Extruder

As the core of the extrusion line, the conical twin-screw extruder melts, plasticizes, and homogenizes the PVC compound. Its unique screw design provides excellent shear and mixing capabilities, ensuring uniform melt temperature and pressure for consistent extrusion. FANLYPLAS extruders are known for their efficiency and reliability.

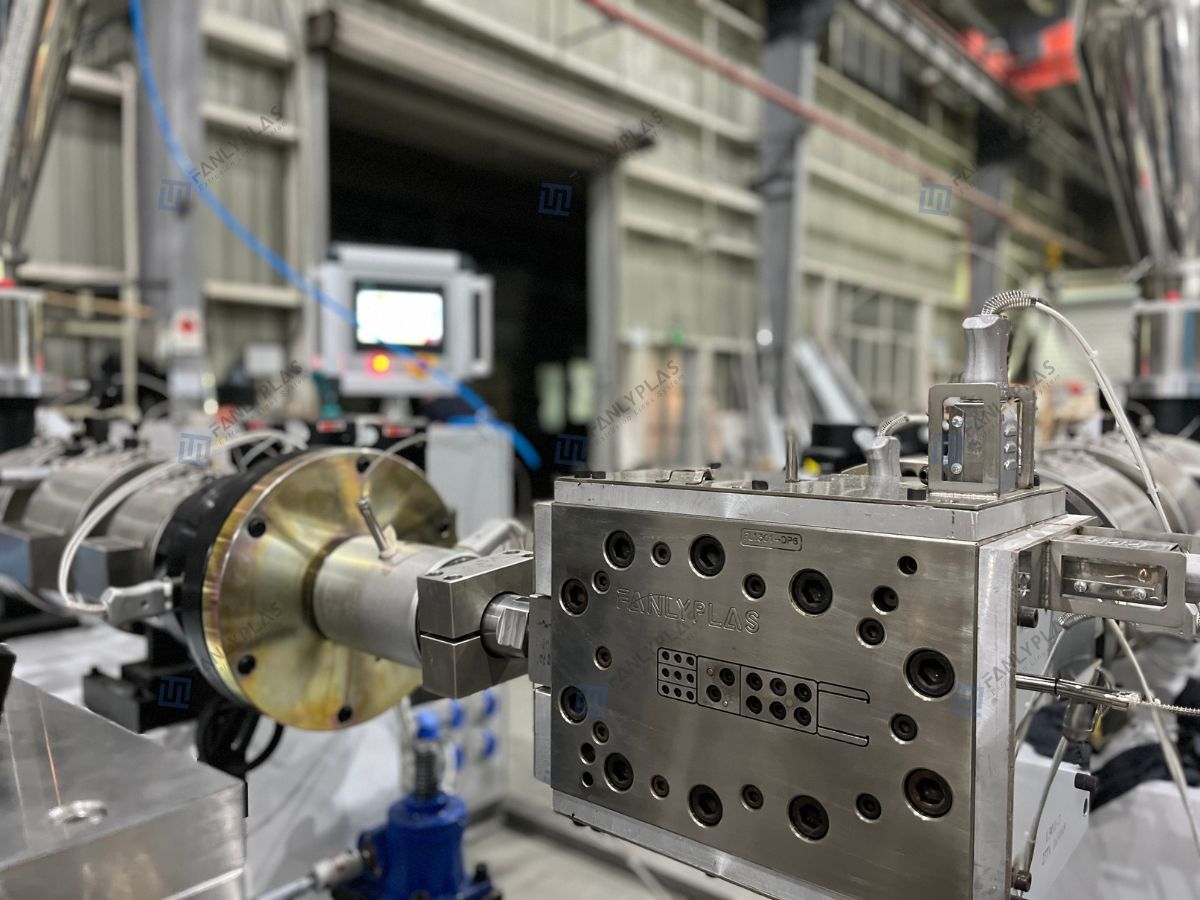

Extrusion Die Head and Mold

The molten PVC material is forced through the die head and mold, which shapes it into the desired profile cross-section. The precision and quality of the mold are critical for the dimensional accuracy, surface finish, and overall appearance of the final product. FANLYPLAS provides high-quality, customized molds.

Vacuum Calibration Tank

Immediately after exiting the die, the hot PVC profile enters the vacuum calibration tank. Here, a vacuum system, combined with cooling water, helps to cool and solidify the profile while precisely maintaining its shape and dimensions. This step is crucial for achieving accurate product geometry.

Haul-off Unit

The haul-off unit continuously and steadily pulls the solidified profile through the calibration tank. It typically uses rubber belts or caterpillar tracks to provide a consistent pulling force, ensuring uniform wall thickness and preventing deformation. The pulling speed is synchronized with the extruder output.

Cutting Unit

Once the profile reaches the desired length, the cutting unit automatically cuts it. Depending on the profile type and production requirements, this can be a saw cutter (for rigid profiles) or a knife cutter (for flexible profiles). Precision cutting ensures uniform product lengths.

Stacker/Collection Unit

The final unit in the line, the stacker, automatically collects and stacks the cut profiles neatly for packaging or further processing. This streamlines the production process and reduces manual labor.

Why Choose PVC Profile Extruder From FANLYPLAS?

Superior Quality & Advanced Technology

ANLYPLAS is committed to providing high-quality PVC profile extruder, utilizing advanced extrusion technology and precise mold design to ensure stable and efficient operation, producing excellent PVC profile to help you stand out in the market.

Customized Solutions & Professional Service

We have an experienced team that can provide tailor-made production line solutions based on your specific needs. Additionally, we offer comprehensive installation, training, and after-sales service to ensure the smooth operation of your production without any worries.

Continuous Innovation & Trustworthy Brand

FANLYPLAS, a well-known plastic extrusion equipment manufacturer in Shanghai, China, has obtained ISO9001 quality management system certification. Choosing us will ensure you have a long-term partner.

Q&A

What quality assurance can you offer, and what brands of components do you use?

Quality is our cornerstone. With over 20 years of manufacturing experience, we build our machines for reliability and performance. We integrate premium components from world-renowned brands like Siemens, Schneider, and Omron to guarantee stability and a long service life. Before shipment, every production line undergoes a rigorous quality control inspection and a complete test run at our factory. We welcome you or your designated third-party to witness this pre-delivery test in person to ensure your total satisfaction.

What kind of after-sales service do you provide for international customers?

We provide comprehensive global after-sales service to ensure your success. Our experienced engineers can travel to your factory for on-site installation, commissioning, and operator training. For long-term peace of mind, we offer lifetime 24/7 online technical support via video call or messaging for any troubleshooting needs. Furthermore, we guarantee a reliable, long-term supply of all necessary spare parts at a reasonable cost, ensuring your production line runs smoothly for years to come.

How can I get a quotation for your PVC profile production line?

Getting a quote is easy. Please contact us via WhatsApp, email, or our website’s inquiry form. To provide an accurate quotation, please include the profile drawings or sizes, your required output capacity (e.g., kg/hr), and any component brand preferences. Our expert team will promptly provide you with a tailored proposal.

What is the delivery time for your machines?

The typical delivery time for a standard PVC profile extrusion machine is approximately 60 to 90 working days after receiving the down payment and confirming all technical specifications. The exact lead time can vary depending on the complexity and customization of the machine, as well as our current production schedule. We will provide a confirmed delivery schedule in our official sales contract.

Let's Build Your Ideal PVC Profile Extrusion Line

Tell us your requirements, and our engineering team will provide a customized technical proposal and a competitive quote within 24 hours.