PVC WPC Profile Production Line

Custom your automatic production line! Made to order. Made to fit.

Introduction of PVC WPC Profile Production Line

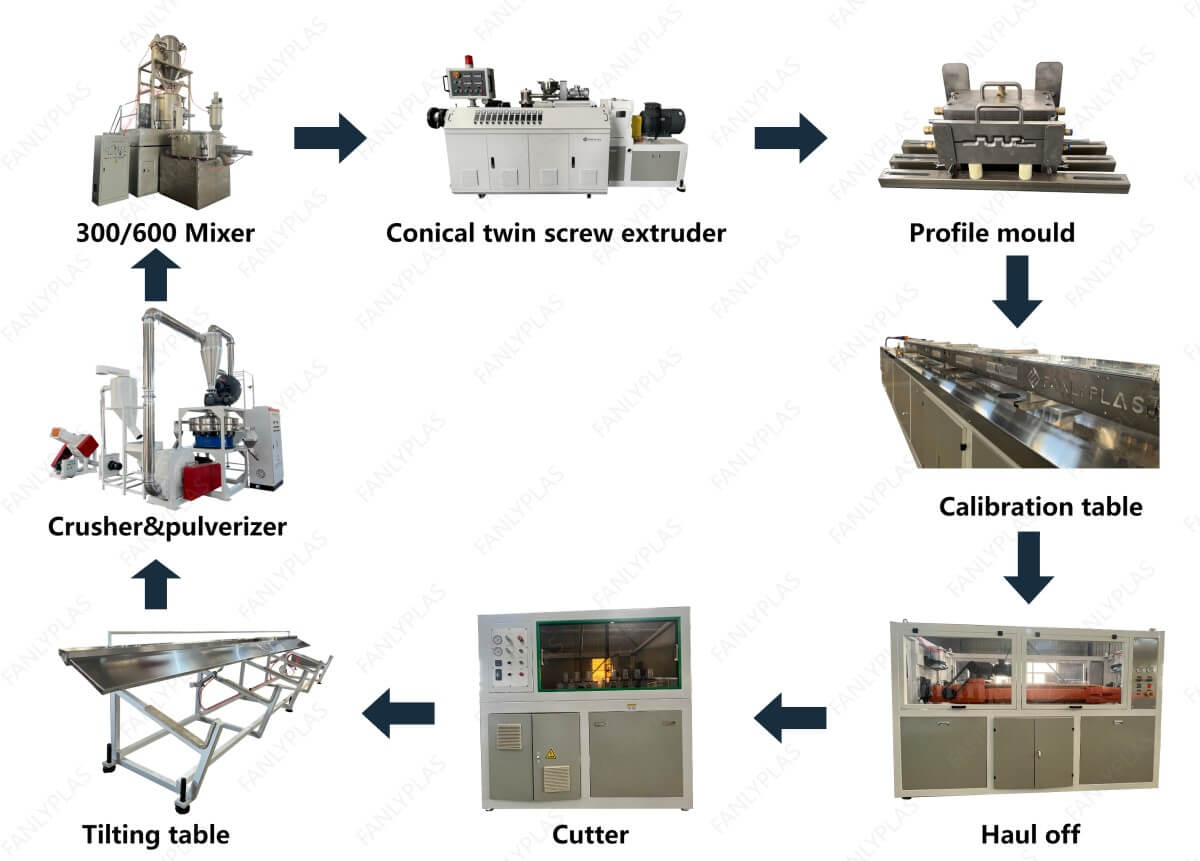

1.FANLYPLAS PVC WPC Profile Production Line is mainly used to produce various plastic profiles. This profile extrusion line has the advantages of stable plasticization, high output, low shear force and long service life in the process of producing plastic profile extrusion.

2.PVC WPC Profile Production Line includes conical twin screw extruder, vacuum forming table, haul off machine, cutting machine and profile stacker, etc.

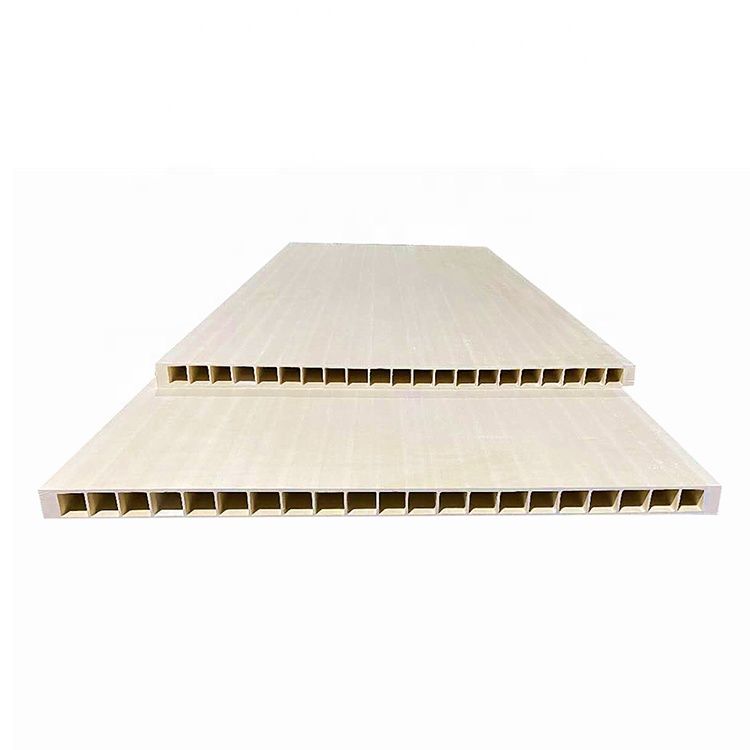

3.PVC WPC Profile Production Line can produce different PVC WPC profiles by replacing screw barrels, molds and auxiliary equipment, such as: PVC WPC window door profile, PVC WPC door panel wall panel profile, WPC decking profile, PVC corner bead profile, skirting profile, etc.

Features of FANLYPLAS PVC WPC Profile Production Line

1.PVC WPC profile production line can adopt different models extruders to meet different kinds of profiles making.

2.The extruder adopts AC frequency conversion or DC speed regulation, and imported temperature controller.

3.Vacuum forming table adopts vortex water cooling system, which is easy for vacuum forming and cooling down.

4.Haul off machine purchase the specially designed caterpillar control system to keep the caterpillars with set pressure to the profiles.

5.Cutting machine synchronization work with the haul off machine and controlled by the PLC system. Cutting machine also sets the dust colloecting device.

6.According to different kinds of profile moulds, the vacuum forming table can be 4meter, 6meter, 9meter, 11meter.

FANLYPLAS Conventional PVC WPC Profile Production Line

Some Pictures Of Plastic Profiles Produced By FANLYPLAS PVC WPC Profile Production Line

FAQS

Yes, we can. You can share us your detailed requirements, then we will offer you the solution accordingly.

Our company is located in Shanghai, China, and we have our own factories in Zhejiang and Anhui. , welcome to visit our factory.

You can come to our factory for on-site testing, and then load the machine on-site for shipping after you are satisfied with the test.

Yes. We will provide complete after-sales service, including machine installation, machine trial running, personnel training, raw material formulation analysing and adjsuting, etc.

Get Extrusion Solutions Or Service Today?

Just leave your needs & questions here, we will back you in short time. (The more details you leave, the better quotation will reach you soon)